|

mail@toyota-club.net © Toyota-Club.Net Oct 2015 - Jan 2019 Let's attach a theme that will stay rather actual in the near future.

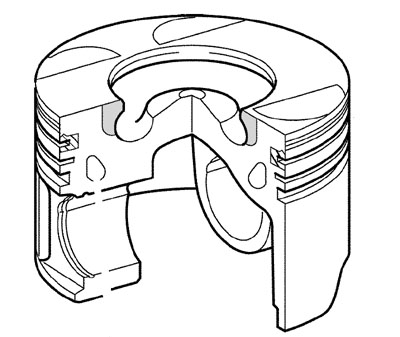

Problem The failure causes the following sudden symptoms: loss of power, engine runs roughly (at three cylinders), loud knock at idle, smoke in the exhaust, crankcase gases pressure strongly rises. When disassembling the engine, there are cracks are detected in one or more pistons (various sizes, up to a local ruptures). The look is radically different from the cases of usual piston melting, and only small local flowing can be observed in the areas of ruptures. The worst - when crack spread to the outer surface of the piston, it makes a deep scuffing at cylinder wall.

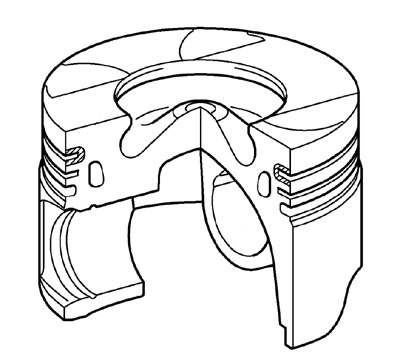

There is not a unique dependence on distance - usually failure occurs at 100-150.000 km, but few cases reported at range 50-100.000 km. The problem recognized by Toyota, and described at technical service bulletins (TSB) EG-0172T-0511-EN on 06.05.2011, EG-0008T-0112 on 19.12.2012/09.18.2014, as well as in adjacent EG-0108T-1211 (for fuel system changes). Considering the circumstances of occurrence, the cause of the problem should be called "inadequate strength margin of pistons" - that is constructive defects caused by mistake during on of engine modernization. Contributing factors are associated with the fuel system, but are secondary. History During 1KD-FTV production, there was various piston modifications installed. (Note: for standard pistons should formally specify the full number with the code of size group at the end (-01, -02, -03), but let's assume some simplification). The first version can be considered as problem-free: 13101-30020 / 08.2000-08.2004 (Euro, Jap) 13101-30040 / 08.2002-07.2004 (Gen) 13101-30050 / 11.2002-12.2003 (Jap) The documentation highlighted that for strengthening the area around the combustion chamber, there was a particular metal-fibrous structure fused in the piston crown.

The following modification coincided with the overall modernization - reduced compression ratio, the euro-modification torque up from 340 to 410 Nm (Japanese market 1KD never forced until the end of the production). The shape of the combustion chamber in the piston was changed essentially, and any mention about the reinforced zone disappeared. 13101-30060 / 12.2003-08.2006 (Jap), 08.2004-08.2006 (Euro) Substitutability - compatible with the following "defective" version -30090. Together with the introduction of the Euro 4 version and a slight output increase (up to 172 hp), most unsuccessful version of the pistons appeared. The phrase in Toyota's description "The strength of the pistons has been optimized through the use of high-strength materials in order to support the improved power output of the engine" today sounds mockingly. 13101-30090 / 08.2006-06.2009 (Euro), 08.2006-07.2007 (Jap). Substitutability - compatible with the next version -30150. Three years later, obviously substandard pistons was replaced by a new revision, but it has not brought success. 13101-30150 / 06.2009-12.2013 Substitutability - compatible with the latest version -30200.

Euro 5 modification of the engine with reduced compression ratio get new pistons and delivered to civilized market till the end of production. The piston problems was not mentioned for this version. 13101-30170 / 10.2010-06.2015 The next revision of pistons to replace -30150 - 13101-30200 / 12.2013-06.2017

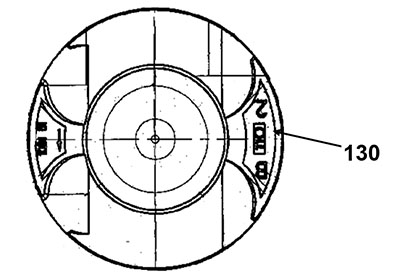

The final (for now) revision of "increase strength" pistons (instead junk 30090..30150 and better 30200) introduced in 2017:

13101-30250 / 2017.06- ID-code at piston top changed from 110 to 130.

Toyota engines review |

|