Eugenio,77

Statistics · Dimensions · Mass · Speed · Maneuverability · Comfort · Condition

In total, over the years of mass-import, about 30,000 American trucks were imported into the Mordor. It is approximately 2.5% of the local fleet of heavy trucks, which today officially numbers about 1.2 million vehicles. Nevertheless, in the late 2000s on the highways US-trucks created a much more significant part of the traffic - 15-20% even in the European part of the country, and clearly dominated in the East. We calculated the share of trucks on today's roads in several regions (about 600 oncoming heavy trucks were included in a random sample): the expected 3% at Europe, about 5% near Georgia border, almost 10% at Far East... Without the same scope, but the trucks continue to work. In general, the real traffic of heavy trucks by brand looks like this (spring'2021, Ural region, ~400 oncoming heavy trucks counted): Volvo - 23%, Scania - 16%, DAF - 14%, MAN - 13%, Kamaz-Axor - 12%, Mercedes - 11%, Renault - 4%, Iveco - 2%, Ford - 1%, MAZ - 1%, Americans - 1%. In the southern regions, a tangible share of Turkish and Transcaucasian trucks noticeably affects the distribution by brands (spring'21, Stepantsminda - Zhinvali, ~550 oncoming): DAF - 26%, Mercedes - 20%, Volvo - 18%, Man - 11%, Renault - 10%, Scania - 9%, Iveco - 3%, Americans - 2%, Kamaz-old - >1%, Ford, MAZ - <1%. If the total number of trucks by brand is not a secret, then the number of vehicles for each model was not specially calculated. Based on the available scattered data, we can roughly estimate the share of specific models of US-trucks at the local market and form a top 10 (which will include 90~95% of all imported trucks).

Some obvious findings: - Like at the truck-homeland, the major brand is Freightliner, the main models - Century Class / Columbia, which together account about a half of all US-trucks. It so happened that in the west there is a little more Columbia, in the east - Century. - Local journalists often forget about the existence of American Volvo (customs statistics do not separate them from European ones, and in US they are traditionally in the shadow of other big brands, several times behind the sales of Freightliner and Peterbilt/Kenworth). Meanwhile, for the local market VN is the second most widespread brand and model of trucks. - Classic Americans make up a very modest share of the truck fleet. Most of them are FLD, a small part - 9900, and a varied fragments from the past. - Cab-overs are represented by 9800, which were popular im mid-2000s, and a small amount of Argosy. Most of the imported trucks belonged previously not to a owner-operators, but to large transport and leasing companies (fleet-operator), which affected the configuration and vehicle health. Trucks bulk import from USA continued within a rather short period of the most successful years and took on the character of a "gold rush". A lot of customers and companies, who had no special experience or were just casual in the business, rushed to the transport market in the expectation that tariffs and loads would continue to grow rapidly. They sold cars and apartments, getting into debt, hoped to recoup their investments in 1-2 year. Companies ordered hundreds of new trucks for future development or to be leasing-providers. Dealers filled the parkings with hundreds of used trucks for future sales. But the real "future" turned out to be the crisis of 2008-2009. The transportation market collapsed, the need to expand the vehicle fleet disappeared - the question became much more urgent of how to sell the loan-bought vehicles, and the already imported trucks were subsequently enough for several years of sales. It is noteworthy that when the economy rose from a knockdown on the new and last spurt in oil prices, imports of US-trucks did not show growth - their share in relation to imports of used Europeans fell to the level of the very beginning of the 2000s. In the meantime, very little remained before the aggresion against Ukraine and disaster of 2014... However, during this period, the state development strategy began to work against any imported trucks. New customs duties and technical regulations, utilization fee and preferential targeted loans... were organically supplemented by the falling currency.

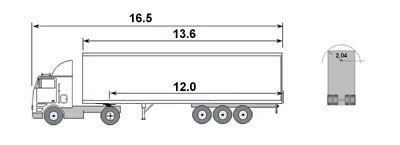

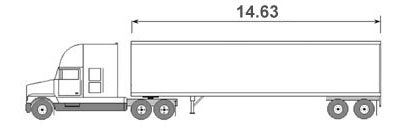

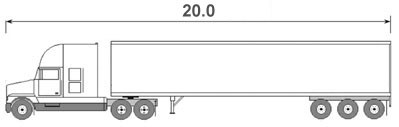

In the countries of the European Union, on the basis of Directive 96/53/EC and its subsequent developments, there are universal restrictions on the length of a road train (tractor + semitrailer) - 16.5 m, as well as on the dimensions of a semitrailer - 12 m from the fifth wheel axle to the rear and no more than 2.04 m to any point in the front. On this basis, the "euro-standard" of a semitrailer was formed - about 13.6 m long with a three-axle, and a truck tractor - two-axle, 4x2 drive type. Three-axle models (6x4 or 6x2) are used, as a rule, as a chassis for dump trucks, construction and special vehicles, or in tandem vehicles.

In the United States, since 1982, there have been only state-specific restrictions on the length of conventional semi-trailers, and federal law set only the low margin of this limit at 48'(§658.13 FMCSA Regulations). At almost half of the states, the minimum value is taken for the limit, and the maximum for today is Oklahoma's 59'6" (~18.1 m). This is how the "american standard" was formed - a semi-trailer of 48'(~14.6 m) with two axles and arbitrarily long 6x4 bonnet-type tractor with a large sleeping compartment (truck). Cabover models were quite widespread before 1980s, but gradually left the US market.

In Russia, only the total length of the road train was historically limited - 20 m. A wide variety of combinations fit into this value: euro-tractor + euro-semitrailer (16.5 m), euro-tractor + american semitrailer (~18 m), truck + euro-semitrailer (18-20 m, depending on the length of the tractor), truck + american semi-trailer (~20 m). In addition, semitrailers with a length of more than 16 m, which fit into the size only with a cabover tractor, were put into operation.

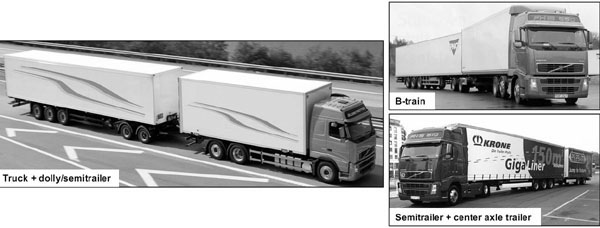

The technical regulation adopted in 2009 was supposed to bring local legislation closest to the common European norms a year later. However, such harsh restrictions even came into conflict with the own business interests of a number of representatives of the ruling regime, therefore, in the revised version of the regulations, the proposed restrictions on the length and maneuverability of road trains were removed. The maximum length of the road train is still 20 m. One could often hear an appeal to a certain "Scandinavian experience" - they say, because in Sweden and Finland, the operation of road trains up to 25.25 m is allowed. But, firstly, only modular trains (options are shown in the illustration below), and purely standard pan-European sizes allowed. Secondly, the length of a tractor + semitrailer trains in Sweden is limited to 24 m, in Finland - to the usual 16.5 m. Finally, in Sweden, climatic conditions are not the most favorable, there are no length restrictions, there are two largest truck manufacturers (one of which is known for its trucks for the North American market) - however, there is no dominance of bonnet-tractors on Swedish roads.

While in Mordor, the large-sized transport appeared en masse only by the mid-2000s, having hit the already formed road and economic infrastructure, laid down in the sovietische era under the then balance of rail, water and road transport, the then weight and size restrictions and the very modest capabilities of red trucks.

Almost everything is fine with the trucks, but... Built under US restrictions on the width (102" - §658.15 FMCSA Regulations), the tractors have a width along the running-boards (non-retractable steps) of 2570-2590 mm. In addition, a variety of body kit elements can come out of 2550 mm, such as fuel tank covers. So, 2-3 extra centimeters of width, if desired, could be found - there were precedents.

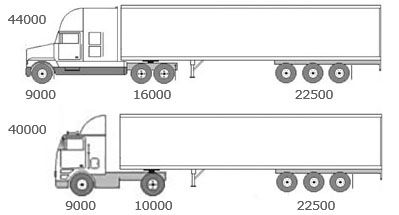

USA have even stricter limits for highway transport (23 CFR Part 658.17): 80,000 lb (36.3 tonnes) gross weight, 20,000 lb (9.1 tonnes) for single axle, and 34,000 lb (15.4 tonnes) for dual axles. For Europe as a whole (Directive 96/53/EC) the maximum total weight is 40 tonnes, the drive axle load is 11.5 tonnes (local regulations may allow more weight). The second, in addition to the extra axle, the commercial merit of American trucks is a rather small curb weight: according to documents, the most common 6x4 truck is 7.0-7.2t, while a modern european 4x2 weights at least 8.0-8.5t, and with three axles it will be another 1-1.5t heavier (in fairness, it would be worth comparing the dry weight, since the difference in the tanks capacity can add half a ton to European). But in principle it is understandable - the huge upper parts of the American truck consist mostly of plastic and aluminum, while the European engineers are traditionally heavily invested in passive safety. As a result, if working within the current legislation, the American tractor allows both to take noticeably larger loads, and to be less scrupulous in placing the load in the trailer. On the other hand, many buyers deliberately purchased trucks for operation with overload (60-80+ tons), so one cannot fail to note their complicity in the triad of the main destroyers of roads (grain carriers, chinese dump trucks, oversize dump-trailers). Not for nothing in the past, among the factory characteristics of the most monstrous trailers was listed "for american tractors". Unfortunately, weight and speed limits do not apply to vehicles carrying out transportation in the interests of representatives of the ruling dom.

Another 20 km/h can be added to this limit without penalty. In Europe, in the absence of uniform restrictions, the maximum speed for road trains is set at 60 to 90 km/h, depending on the country and road category. And back in 1992, a directive for the EU countries (92/6/EEC) came into force, prescribing the mandatory installation of speed limiters on heavy vehicles. The current version (2002/85/EC) reads as follows:

In addition, documentary control of the driving modes, work and rest of the driver is carried out using mandatory tachographs, the introduction of which has been going on since 1985 (EEC 3821/85 rules and their development). In the United States, speed limits are set by each state and vary considerably. In some regions, heavy trucks and road trains are segregated from other road users, in others they are subject to general rules on a par with cars (NHTSA summary). Thus, the maximum permitted speed for trucks ranges from 55 to 75 mph (88-120 km/h), and an additional limitation for HMR is possible. At the same time, federal legislation does not put requirements for the installation of limiters. In practice, most american trucks gain 110-120 km/h even under load, and some outstanding examples are capable to run 140-160 (making "100mph" on a truck is considered a kind of fetish even in US).

It would be naive to expect that vehicle with such capabilities will be operated within the margins of the traffic rules or at least common sense. Before the era of the road-cameras, truck drivers were able to maintain a cruising speed of more than 100 km/h regardless of the background on which the names of settlements were written... Of course, now the chinese experience of total surveillance is being actively adopted, but even so, the eternal race for profit does not stop, but only breaks down into a series of stages.

At one time it was planned to introduce requirements for the maneuverability of vehicles, which were in line with European standards (directives 96/53/EC-2002/7/EC and their development):

It is easy to guess that road trains of the european format fit into this size. But what about American tractors. Alas, the maneuverability of the trucks is a huge and irreparable drawback. Many of them require for a turn a circle radius twice greater then a standard cabover tractor. Of course, the maneuverability of road trains also deteriorate significantly. There a few illustrations below from the North American Roadway Design Manual chapter on truck maneuverability and how it counts in road design. These official guidelines help to draw objective conclusions about how much space is needed for the successful operation of trucks or long semi-trailers. In general, some relatively compact trucks were able to meet the Euro-standard even as part of a road train (with a Euro-semi-trailer), but long-wheelbase tractors, American-style long semi-trailers - turn out to be the embodiment of evil. - Oversized road trains hardly perform their direct functions in the conditions of terminals built for freight transport of traditional dimensions, not to mention the classic old industrial zones . Sometimes it comes to the point that truck drivers hire shunting euro-tractors to supply semi-trailers for loading / unloading. - In urban conditions, trucks, in principle, are unable to move without systematic traffic violations (such as driving into the oncoming lane when cornering). Long semi-trailers, even when paired with conventional tractors, force you to build unconventional trajectories and severely cut the inner edge of the turn. Actually, all the maneuvers of American heavy trucks in the city are based only on the goodwill and fear of the rest of the traffic participants.

Of course, the local truck trade-union fantasies looked pretty:

Only since the mid-2000s, there have been enough suburban cargo terminals, enough regions with harsh conditions, long-routes and other areas of rational use of bonnet tractors. However, for some reason, faster than the share of trucks in the cargo fleet grew, their share was arriving on shuttle flights on the city streets. The problem was in the pathological psychology of the mass of carriers who took a car with a two-meter sleeping bag instead of a delivery truck only because of the low price; who needs two driving axles only to comply permitted axle loads; who are physiologically incapable not todeceive the customer:

Can be heared that "two driving axles are especially convenient in mountainous conditions" - but in addition to the axles, there are at least 6-7 meters of a tractor sticking out in front of them. And how happy the oncoming drivers are, seeing a truck maneuvering across the entire width of the carriageway behind a closed cornering... And a few words about vertical maneuverability. In the American tradition, the "front overhang" of the semitrailer (the shortest distance from the pin) is ~910 mm, in the European - about 1600 mm. When some particularly outstanding trucks were coupled to Euro-semi-trailers by especially outstanding drivers, the gap turned out to be so small that when the truck was "folded" at the exit, the semi-trailer contacts with the fairings of the tractor.

Europeans can only oppose a relatively narrow shelf with a small refrigerator and a locker, closing drawers above the windshield, good autonomous heater. And, transmission selector on the steering wheel, a flat floor and a two meters ceiling, even for top series, became the norm not so long ago, and before that, an engine tunnel, a gear-poker or a pedestal with a gear lever took an already meager reserve of free space. However, the owners of stock fleet versions of trucks could only dream of custom luxury. In addition, the imported vehicles were carefully gutted from the panel to the rear wall; lost additional appliances, a coffee machine, a microwave oven, a refrigerator, a TV - this is understandable, but sometimes even the plastic bedside tables were removed.

• Ergonomics. With the impressive dimensions of the truck superstructure, the actual working cabin is much narrower (and even cramped) than european, the working space is arranged with the traditions of the second half of the last century. The area and shape of the glazing, especially on the classics, does not reach the level of euro tractors, although with such a dimensions it would be desirable to have better visibility. The optics do not formally comply with Euro-standards, and, to put it mildly, do not have sufficient efficiency.

• Gearbox. The vast majority of imported US-trucks were equipped with non-synchronized manual transmissions and clutch without booster. In the conditions of hypothetical interstate-routes, this may not be so important - the clutch is squeezed out once when starting off, and then the gears are changed only by selecting the crankshaft revolutions . But in Mordor the road traffic looks like Europe more - many kilometer traffic jams (stau), city traffic, traffic lights... Today, even light vehicles with synchronized manual gearbox and light clutch pedal only buy because of financial despair. But why so expensive professional tool as truck makes each once to squeeze the pedal with the effort of a weightlifter and tinker with the gearshift mechanism of the WWII epoque, at the same time trying not to grind anyone with a twenty-meter train? "Three-pedal robots", which required squeezing the clutch at start-off and stop, were present in the market in minimal quantities, and their worthness seems to be very doubtful. Full-fledged 2-pedal variants did not have time to become widespread until the end of the era of US-trucks in Mordor. Yes, in the cab of a euro-tractor you cannot relax so fully, make pauses, bother with the housework, bask in the process of the engine overhaul in the middle of the frozen tundra... But the Europeans were the first who realize that with 40 tons behind backs it would be safer for those around them not a brutal cowboy, but the driver of an agile, soft, quiet tractor with an automatic transmsission and a full set of active safety equipment. |

|

|

|