|

Eugenio,77

mail@toyota-club.net

© Toyota-Club.Net

Jan 2016

Priorities

Ever since the introduction of the first Prius impression produced that Toyota likes James Atkinson much more than Ralph Miller. And gradually "Atkinson cycle" of their press releases was spreaded to the whole journalistic community.

- Toyota officially: "A heat cycle engine proposed by James Atkinson (U.K.) in which compression stroke and expansion stroke duration can be set independently. Subsequent improvement by R. H. Miller (U.S.A.) allowed adjustment of intake valve opening/closing timing to enable a practical system (Miller Cycle)."

- Toyota informally and anti-science: "Miller Cycle engine is an Atkinson Cycle engine with a supercharger".

However, even in the local engineering environment, "Miller cycle" has existed since time immemorial. What will be more correct?

In 1882, British inventor James Atkinson proposed the idea of increasing the efficiency of the piston engine by reducing the compression stroke and increasing the expansion stroke. It was supposed to implement complex mechanisms of piston drive (two "boxer" pistons or piston with a crank-rocker mechanism). Built engines showed an increase in mechanical losses, over-complex design and power reduction in comparison with the other engine designs, so the spread is not received. Known Atkinson patents refer specifically to designs, without consideration of the theory of thermodynamic cycles.

In 1947, American engineer Ralph Miller has returned to the idea of reduced compression and continued expansion, but it is not proposing to implement due to the kinematics of the piston drive, but by specify valve timing at engines with conventional crank mechanism. Miller patents considered two options - with early (EICV) or late (LICV) closing of the intake valve. Actually, both versions mean decrease of the actual (effective) compression ratio with respect to geometrical. Understanding, that the reduction of compression will result in loss of engine power, Miller initially focused on boost motors, in which the loss will be compensated by the compressor. Theoretical Miller cycle for spark ignition engine is fully consistent with the theoretical cycle of Atkinson engine.

By and large, the Miller / Atkinson cycle is not an independent cycle, but a variety of known thermodynamic Otto and Diesel cycles. Atkinson is the author of the abstract idea of the engine with a physically different compression and expansion strokes. The real workflow in real engines used in practice to this day - it is suggested by Ralph Miller.

Principles

At Miller cycle with reduced compression, the inlet valve is closed significantly later than in the Otto cycle, due to which part of the charge is returned back into the intake port, and the actual compression process begins at the second half of stroke. As a result, the effective compression ratio is lower than the geometric (which, in turn, is equal to the expansion ratio of the gases at the work stroke). Reducing of pumping losses and loss of compression provides increasing in the thermal efficiency of the engine for about 5-7% and the corresponding fuel economy.

|

|

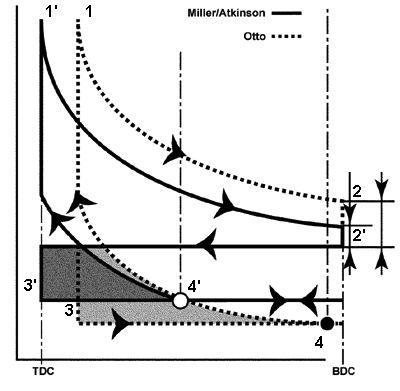

Conditional indicator diagrams for Miller cycle and Otto cycle

|

We can reiterate the cycle difference keypoints. 1 and 1' - combustion chamber volume at Miller-cycle engine is smaller, geometric compression ratio and the expansion ratio is higher. 2 and 2' - gases perform useful work on a longer stroke, so there is less residual losses at exhaust. 3 and 3' - inlet vacuum is less due to smaller throttling, so the pumping losses are lower. 4 and 4' - closing of the intake valve and the beginning of the compression begins in the middle of stroke, after reverse displacement of the charge.

Of course, the displacement causes falling of engine output, and for atmospheric engines such cycle makes sense only in a relatively narrow range of partial load. In the case of constant valve timing, it can be compensated by only using of charge. For hybrid models, lack of traction in adverse modes is compensated by electrical drive motor.

Realization

In conventional Toyota engines (1990s) with fixed phases and Otto cycle, the inlet valve closes at 35-45° ABDC (at a crank angle), the compression ratio is 9.5-10.0 (effective is equal to geometric). In more modern engines with VVT possible range of intake valve closing is widened to 5-70° ABDC, the compression ratio increased to 10.0-11.0.

In hybrid models engines, working by Miller cycle only, the range of intake valve closing is 80-120°... 60-100° ABDC. The geometric compression ratio - 13.0-13.5.

By the mid 2010s, new engines introduced with a wide range of variable valve timing (VVT-iW), which can operate both by Otto and Miller cycle. At atmospheric versions the range of intake valve closing is 30-110° ABDC when the geometric compression ratio is 12.5-12.7, at turbo - respectively, 10-100° and 10.0.

Toyota engines review

·

AZ ·

MZ ·

NZ ·

ZZ ·

AR ·

GR ·

KR ·

NR ·

ZR ·

AD ·

GD ·

A25.M20 ·

G16 ·

M15 ·

V35 ·

|

|

|