|

Eugenio,77

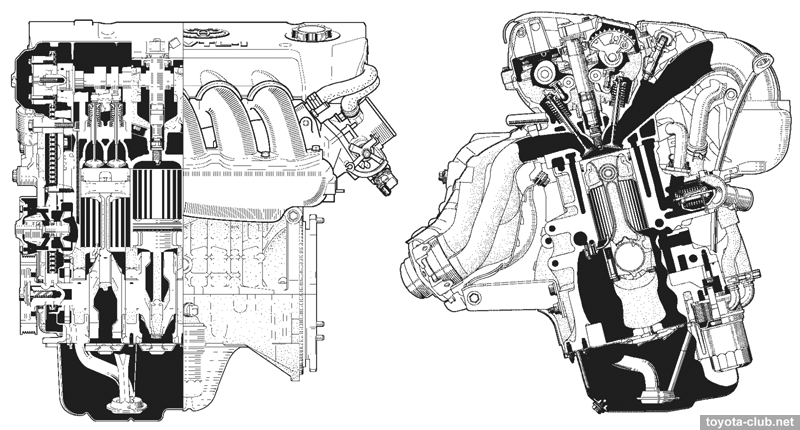

1ZZ-FE (1.8 EFI VVT) - transverse, with traditional multipoint injection, for initially FF cars. Produced since 1997 to the second half of 2000s. Installed in: Allion/Premio 240, Celica 230, Corolla 110U..130..140, Corolla/Fielder/Runx/Allex/Spacio 120, Isis, Lotus Elise, Matrix 130, MR2 30, MR-S, Opa, Pontiac Vibe, RAV4 20, Vista 50, Voltz, Will VS, Wish 10. 3ZZ-FE (1.6 EFI VVT). Installed in: Avensis 220..250, Corolla 110..120..140, Corolla Verso 120..10. 4ZZ-FE (1.4 EFI VVT). Installed in: Corolla 110..120, Corolla/Auris 150.

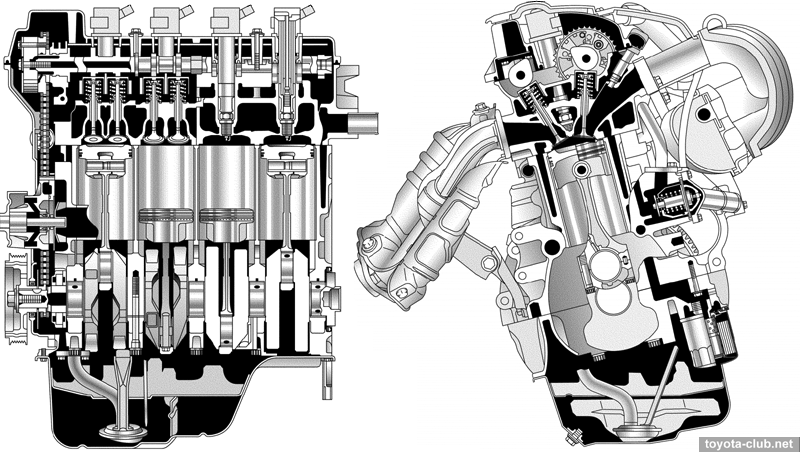

Engine mechanical The cylinder block - aluminium "open deck" with thin cast iron liners. thin-walled cast iron liners.It was the second, after a series of MZ, Toyota experience to introduce mass "alloy engines. It was the second after MZ series experience of mass "alloy" engines. The liners are fused into block and their special rough outer surface promotes strong connection. Advantage - engine weight reduced to ~100 kg instead of 130 kg of iron cast predecessor of the same displacement.

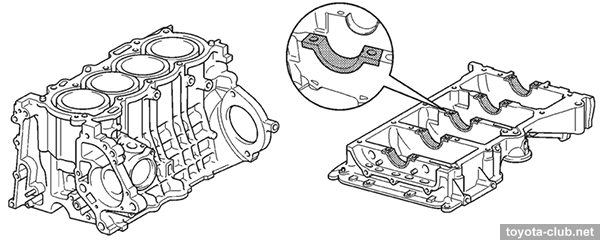

A distinctive feature of the new generation - "open deck" - open top of cooling jacket, that sufficiently decreases stiffness of the block, but it allows to cast block in the mold. Traditional "close deck" blocks are stronger and more reliable, but more time-consuming in preparation of disposable casting molds, have the larger tolerances and require more subsequent machining of surfaces and bearing beds. Another ZZ feature - a massive crankcase combining the crankshaft main bearing caps. Parting line extends along the axis of the crankshaft. Aluminium (light alloy) crankcase is made integrally with fused in steel main bearing caps, and increases the rigidity of the cylinder block.

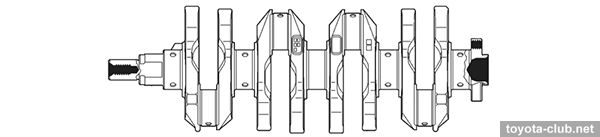

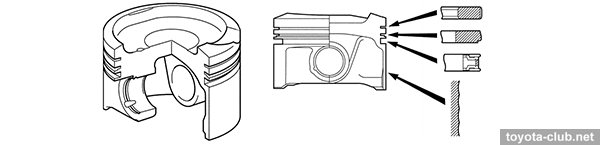

1ZZ-FE is "long-stroke" engine - cylinder bore 79 mm x piston stroke 91.5 mm. This contributes to higher torque at low rpm, reduces the heat loss through the walls of a more compact combustion chamber. On the other hand, due to the high average speed of the piston the requirements to piston rings condition increased. The idea of friction minimizing and compactness became predominant, so diameter and length of the crankshaft journals was reduced - respectively, increased unit loading and wear intensity.

To reduce losses due to piston long stroke the skirt was cutted, which is not good for its cooling. In addition, the T-shaped in projection pistons begin to knock when shifting at dead center much earlier (at lower mileage) than their classic predecessors of 1990s.

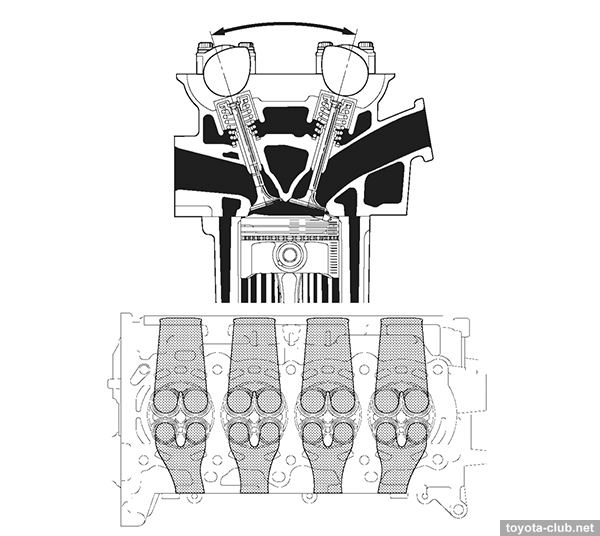

The pistons are connected to the rods with fully floating pins. The connecting rod caps are mounted by bolts (without nuts). The great disadvantage of all new Toyota engines - their "disposable". Reboring possibility does not provide, proper replacement of liners is impossible in principle (of course, in despair, these engines are subjected to overhaul, with liners replacement using non-original parts or matched counterparts from other brands). The problems exist even with oversize crankshaft bearings. Cylinder head is made of aluminum, alloy. Combustion chamber - conical (at the approach of the piston to the top dead center, the mixture is pushed to the center of the chamber and forms swirl near the spark plug, that contributes the more rapid and complete combustion). The compact size of the chamber and the piston shape (forming mixture flow near the wall - at an early stage of the combustion pressure rises evenly, att late increases the combustion speed) contributed to reduce detonation probability.

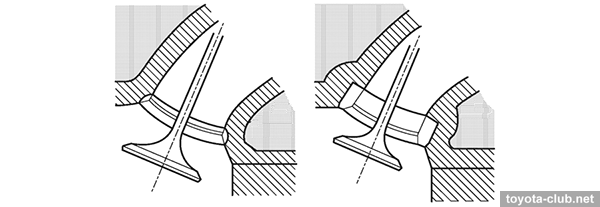

Design of the valve seats is interesting. Instead of traditional steel press-fitted, 1ZZ-FE have so-called "laser-clad" valve seats. It several times thinner than usual and contribute to a better cooling of the valve allowing to transmit heat into the body of cylinder head not only via the valve stem, but also via valve head. Also, despite the small diameter of the combustion chamber thin valve seats allowed to increase the diameter of the intake and exhaust ports, together with the decrease of valve stem diameter (to 5.5 mm) that improved air flow through the port. Naturally, this unit is absolutely not repairable.

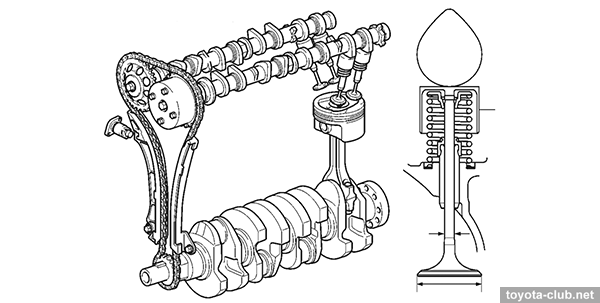

Timing drive - 16-valve DOHC. Reduced valve weight made possible to reduce the force of the valve springs, a small width of the camshaft cams (below 15 mm) means a reduction of friction losses. In addition, Toyota replaced valve adjusting shims by set of "adjusting tappets" of varying thickness, which combine the functions of the former valve lifters and shims (this would make sense for high-rpm forced engine, but in this case, just make the valve adjusting too complex and expensive procedure, so the owners often ignore its necessity).

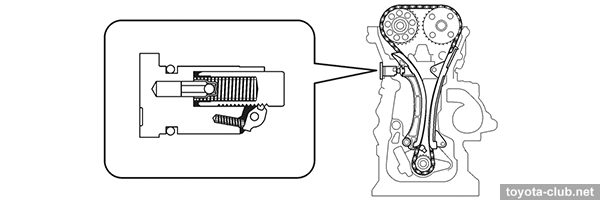

The next radical innovation for Toyota - timing drive by a single roller chain (pitch 8 mm) with outer hydraulic tensioner (equipped with a ratchet and preload spring) and lubrication nozzle. In theory, this means higher reliability compared to belt drive and the rejection of the planned replacements. But in practice... About the increased noise it is unnecessarily to talk. Even the Toyota's tensioner has not long life-time. Subjected to wear the damper and tensioner slipper was installed. But the main problem - chain "stretch" (depending on the chain length). For OHV with lower camshaft in the block and short chain it is not problem, but in conventional DOHC long chains have to be used. Some manufacturers install the intermediate sprocket and use 2-3 relatively short chains - at the same time it allows to reduce the diameter of the driven sprockets but makes problems of increased noise, increased the number of elements, the reliability of additional sprockets mounting), some install belt chains... However, ZZ chains is simple and long.

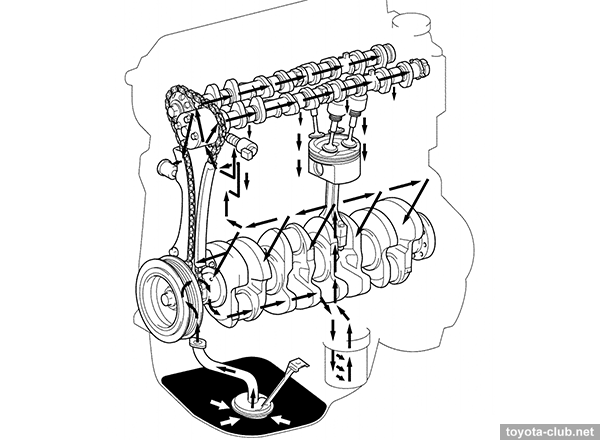

Although the chain implies a reduction of maintenance cost, but in fact the opposite happened... Sometimes the chain replacement is not required even before 200.000 km mileage, but more often the critical stretch occurs at 100-150.000 km range (which show up as excessive noise and trouble codes related valve timing, due to crankshaft and camshaft correlation failure) Together with chain replacement it would be appropriate also replace other components (sprockets, tensioner, guides), as used ones contribute to a rapid wear of a new chain, but as the inlet camshaft sprocket is assembled with VVT actuator , so most owners does not follow this recommendation . The first 1ZZ-FE for overseas market (type '97 for ZZE110, produced until 08.1999) have fixed timing without VVT, but type '98 was already equipped with VVT-i (Variable Valve Timing). Sprocket with VVT actuator is mounted to intake camshaft, variable timing range - 40°. More about Toyota VVT-i operation - As a means of achieving balance between low-rpm torque and high-rpm power output, VVT is welcome, but do not forget about stronger requirements to the motor oil and oil channels cleanness. Lubrication system Cycloid oil pump in chain cover is driven directly by the crankshaft. The oil filter is located vertically under the engine (which partly solves the traditional problems of oil pressure rising after the start).

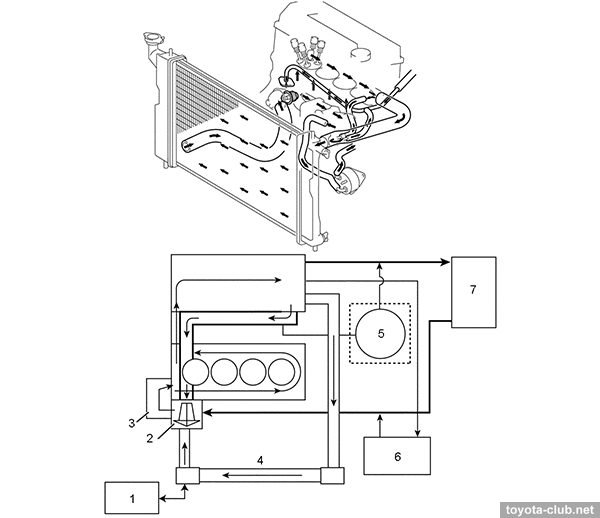

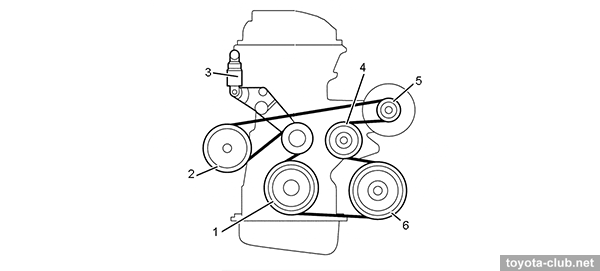

Cooling system The coolant flow passes through the block via U-route, covering both sides of the cylinders and improve cooling. The pump is driven by common serpentine belt, thermostat - "cold" (80-84°C) mechanical, throttle body is heated.

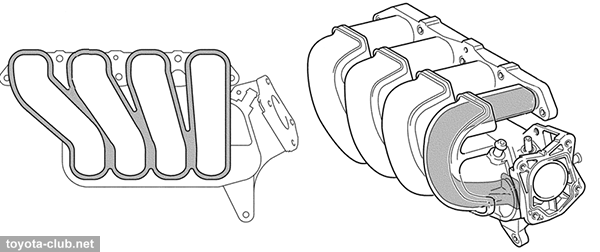

Intake and exhaust Beside to classic motor series new layout of manifolds is noticeable - intake in the front, exhaust in the rear. To speed up the heating of catalyst after starting, it must be as close as possible to the engine. But for small engine compartment so "red-hot" neighbourhood is not the best solution, so the catalyst was moved below the engine and underfloor. The long intake duct increases engine efficiency at low and medium rpm, but with front intake manifold location it is some difficult to make it sufficiently extended. So, instead of the traditional cast manifold with "parallel" pipes (as for 1ZZ-FE types '97 and '98) later on was installed "spider" with four aluminium ducts of equal length, welded to the common cast flange. Plus - ducts made of rolled metal have a much smoother surface than cast, minus - not always perfect welding between the flange and pipes.

However, since the type '00 Japanese simplified the design by replacing a complex metal manifold by ordinary plastic one. It allows to save alloy metal, simplify technology and reduce the heating of the intake air due to the lower thermal conductivity of plastic.

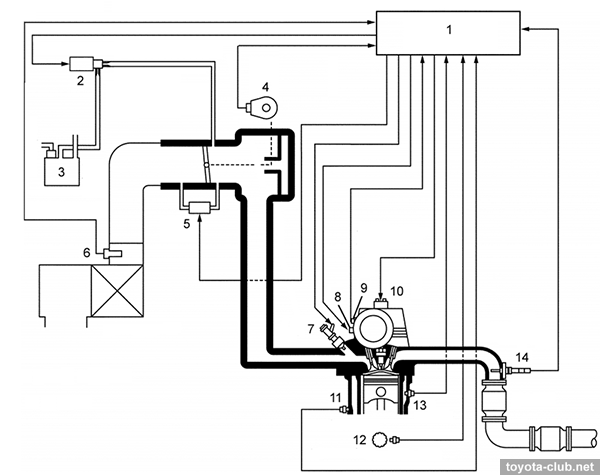

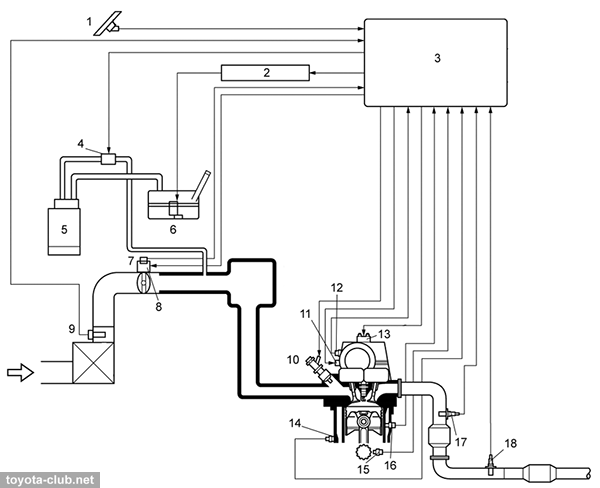

Fuel injection system The control system - "L-type SFI", with mass air flow sensor (MAF) "hot wire" type, combined with intake air temperature sensor.

Fuel injection - traditional multipoint, sequential under normal conditions. The injection can be performed synchronized (once per cycle at the same position of the crankshaft, with managed time of injection) or unsynchronized (by all injectors simultaneously).

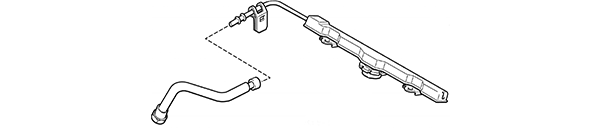

The fuel system was significantly modified in comparison with older series. To reduce heating and evaporation of the fuel, Toyota refused to use fuel return line and the vacuum pressure regulator. Now, the pressure regulator is set to fuel pump unit submersible in the tank, combined with the fuel filter. There are "quick" type connectors in the fuel line.

Pulsation damper mounted on fuel rail.

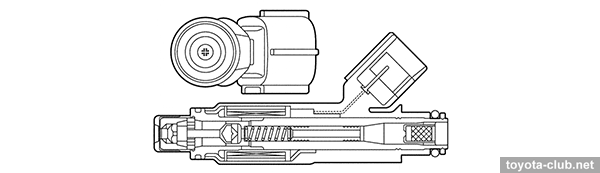

The injectors with multi-hole nozzle are used to improve dispersion of fuel. It are installed in the cylinder head directly.

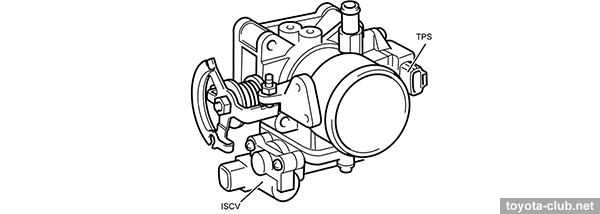

Throttle drive for type '98/00 - mechanical, idle speed control - classic "rotary solenoid".

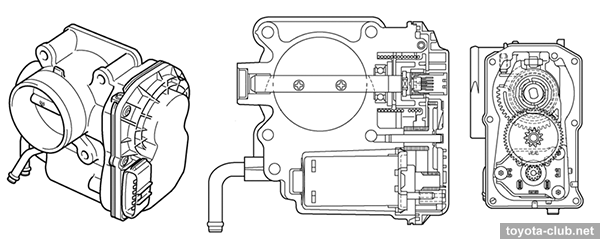

For 2WD models, launched after 2004, electronic throttle control (ETCS) unit was installed. DC motor, dual-channel contact-less position sensor (Hall effect), separate accelerator pedal position sensor. ETCS performs some functions of traction control (TRC) and, on later models, stabilization (VSC).

At first half of 2000s "flat" piezoelectric knock sensor was introduced, unlike the old type of resonant knock sensors it feels a wider range of vibration frequencies.

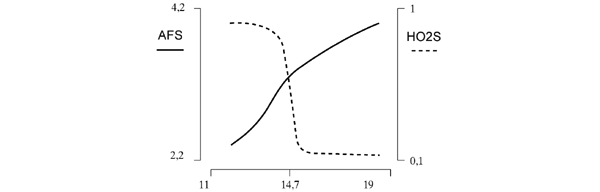

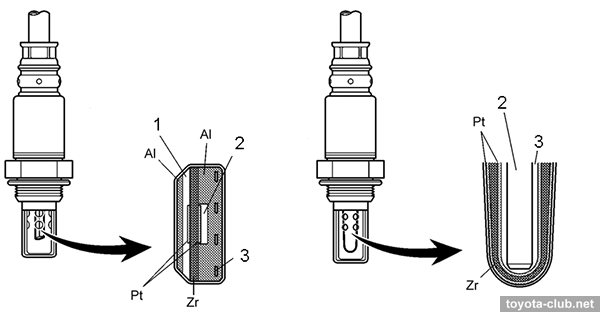

Oxygen sensor (89465) installation variants - upstream catalyst (domestic market) or upstream and downstream catalyst (overseas markets). ETCS versions for domestic and North American market at some point was equipped with AFS sensor (89467).

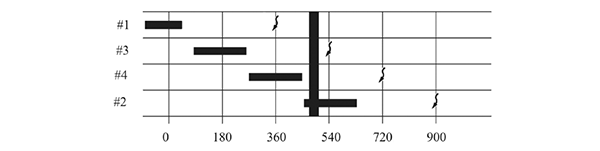

The ignition system - at type '97 and '98 distributorless DIS-2 (one coil for two spark plugs), but all engines since type '00 was equipped with DIS-4 - separate ignition coil for each cylinder. Plus - the accuracy of determining the ignition timing, the lack of high-voltage wires and mechanical rotating parts (excluding sensor rotors), a smaller number of operation cycles of each coil. Minus - the coils (combined with igniters) are subjected to significant heating inside the plug holes of cylinder head, ignition timing can not be adjusted manually, engine is more sensitive to the spark plugs condition. In practice, for traditional distributor ignition system the coil (especially outer) almost never was in the broken parts list, but for DIS of any manufacturer the replacement of ignition coils (or even "ignition modules") is familiar and regular part of maintenance. Spark plugs: for DIS-2 - two-electroded (Denso K16TR11), for DIS-4 - usual (Denso K16R-U11 / NGK BKR5EYA11). Auxiliary drive (alternator, compressor, water pump, power steering pump) - by single serpentine belt. Plus - compact size, minus - more load to single belt, tensioner life-time, inability to remove belt from one seized up unit.

Summary So what is the result? Toyota created the modern, sufficiently powerful and economic engine... But the story of oil consumption was so loud, that made tainted reputation of all new series. It is good, that "planned" oil burn at least not immobilize the car, so in the canonical triple of Toyota's engines ZZ are at intermediate position - between the successful NZ and more unsuccessful AZ. The struggle between manufacturability and reliability ended not in favor of the consumer. And it's unfortunate that no more alternative for new generation engines...

Minimal differences in comparison with 1ZZ-FE: - Crankshaft with 4 counterweights instead of 8. - Injectors with 4 holes in the nozzle instead of 12. Since 2004 3ZZ-FE was equipped with ETCS. 4ZZ-FE was remained with mechanical throttle until the pruduction end. In addition, it stood out by its Bosch engine control system and ignition system with FR8KCU spark plugs.

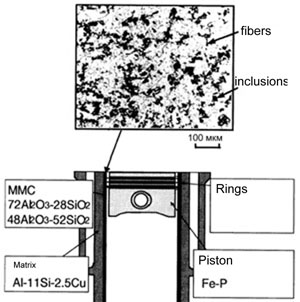

After implementation of new engines generation, a question arose of new forced engine for FF models to replace 4A-GE and 3S-GE. It had to have the same dimensions as the 1ZZ-FE, unit output as "best world analogues" and the minimal weight. Of course, not using the boost, and combining high power at high rpm with a sufficient torque at low rpm. First 2ZZ-GE, created with the traditional participation of Yamaha, was introduced at overseas with new Celica 230 in 1999. ZZ features described above. but the new motor had many radical differences... The main pride - new aluminium linerless block on MMC base (this is not the "Mitsubishi Motors", but "composite" material with alumino-silicate fibers and inclusions).

1ZZ-FE is a very long-stroke engine, so further forcing by rpm was impossible with the same bore/stroke ratio. As a result, the bore was maximally increased so the wall thickness between cylinders was reduced to 5.5 mm. Thinner is impossible because gasket will not seal head/block joint. Even if at this place could be inserted a liner, the bridge temperature would exceeded all limits - so Toyota made a kind of "composite liner". The main problems are related to molding nuances and, in the absence of traditional cast iron liner, does not fixed: - uniformity of solidification (causes hole forming) - porosity (the solidification process is slowed near the inclusions with lower thermal conductivity) - cracks (due to different solidification speed near MMC inclusions and in the main aluminum volume, at the mold surface and inside it)

With molding defects Toyota fought by strong pre-heating of molding form, laminar filling it with liquid metal, vacuum-degassed forms etc. MMC had low wear resistance - as known iron cast liner or block retains hone grid for a long times, but in the full-aluminium block the grid even was not "cutted" but "collapsed" (the surface plastically deformed). This "feature" can not be eliminated, so Toyota achieved maximum possible resistance by composition - and declared it as "sufficient". The piston for this engine was also manufactured by MMC technology, and the outside of the skirt was coated with phosphorus- and iron-containing applied coating compound to increase the hardness. Quite a long time was spent to adjust so-called "liner"/piston rings pair to provide wear due rings instead deliberately weak cylinder wall. The second revolutionary innovation was VVTL-i system (Variable Valve Timing and Lift). Traditional VV"T" part is similar to 1ZZ-FE and responsible for improving low rpm torque, additional VV"L" improves maximum output at speed over 6000 rpm by increasing the valve lift from 7.6 mm to 10.0 / 11.2 mm. VVTL mechanism is rather simple. For each pair of valves there are two cams with a different profile on the camshaft ("normal" and "aggressive"), and on a rocker - two different followers (respectively, roller and slider). In the normal mode, the rocker (and valve) is driven by "normal" cam through roller follower, and spring-loaded slider idling moves in the rocker. In the power mode the locking pin is moved by oil pressure and backs the sliding follower rod rigidly connecting it with the rocker. When pressure is removed, the spring presses the pin out and sliding follower is released again. Different followers using because roller (with needle bearings) allows less friction loss, but at the same height of the cam profile provides less filling (mm*degrees), but at high speed the friction losses are almost equalized, so to maximizing the output the slider becomes more advantageous. Roller follower is made of hardened steel, slider is made of antiscoring ferroalloy but requires to use special spraying system installed in the cylinder head.

The most unreliable part of VVTL was the locking pin. It can not move to operating position for one rotation of a cam, so inevitably occurs a partial overlap collision of rod and pin, causing progressive wear. Eventually the worn pin will always be wrung out by rod in the initial position and not be able to fix it, so will always operate only the low-rpm cam. Toyota tried to solve the problem by thorough surface treatment, decreasing the weight of the pin, increasing the oil pressure in the line, but without final success. In practice, failures of the rocker pins still occurs. The second common defect - rocker arm shaft mounting bolt break, causing shaft turns freely, so the oil supply to the rockers stops and VVTL does not work (also lubrication of the unit is deteriorated). The rest of the improvements can be considered less significant. Modified oil sump to avoid air capture by oil pump during acceleration. The intake manifold with a large resonator, the partition in the exhaust to reduce heat loss and faster catalyst warm up.

The rubber spacers between the intake manifold and cylinder head to improve noisiness. Summary (2ZZ) It seemed, Toyota made a new, high-tech, quite compact, lightweight and powerful engine. Moreover, unlike predecessors it had rather "flexible" character with normal torque at low rpm. But, except for the other ZZ features: - increased compression ratio (11.5) requires high octane gasoline (RON 95). - "raw" and non-reliable design of VVTL rockers - "Disposable" as for all new engines, is compounded by high loads and using of specific materials - so it is the most delicate of Toyota's engines. As experience shows, in terms of reliability 2ZZ-GE and 4A-GE/3S-GE are worlds apart.

Toyota engines review |

|