Eugenio,77

This brief review focuses on Toyota engines produced since 1990s to 2020s. The data is based on experience, statistics, reviews of the owners and repairers. Edition 5th, updated.

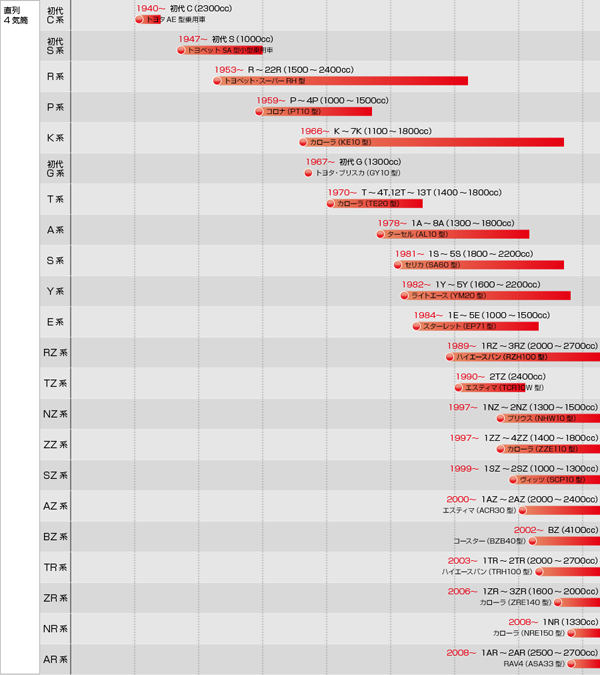

A ·

E ·

G ·

K ·

S ·

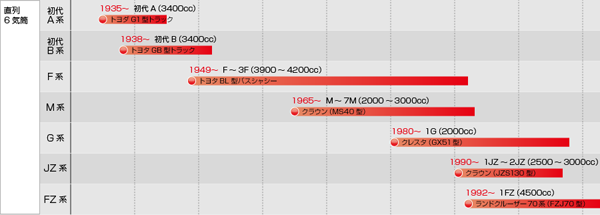

FZ ·

JZ ·

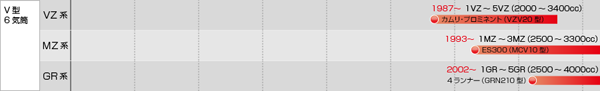

MZ ·

RZ ·

TZ ·

VZ ·

UZ ·

AZ ·

NZ ·

SZ ·

ZZ ·

AR ·

GR ·

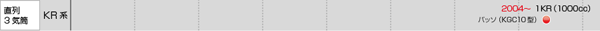

KR ·

NR ·

TR ·

UR ·

ZR

Since the beginning of the mass import of Japanese cars (early 1990s) few conventional generations of Toyota engines changed:

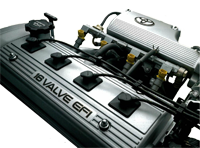

4A-FE (1988-2001) - the most known engine of the series, mass, deservedly beloved, without significant structural defects, easy to maintenance; small drawbacks - a tendency to increased wear of camshaft beds, non-floating piston pins. 5A-FE (1988-2005) - the basic motor, produced not only in Japan, but at Chinese factories for Southeast Asian market and joint models. 7A-FE (1994-2002) - later modification with increased displacement. The optimal versions of 4A-FE and 7A-FE were used for Corolla family. However, being installed in Corona / Carina / Caldina, they got the "LeanBurn" system, designed for lean combustion and helps to save fuel at traffic jams (more about feature - "Toyota 4A-FE Lean Burn", at which models installed - "Lean Burn on Toyota A engine series"). But the Japanese harmed consumers - many owners of these engines were faced with the so-called "LB problem", which reveals as specific power loss at medium rpm, the cause of which and cure were unknown thoroughly - whether the poor quality of gasoline, whether problems in fuel system or ignition (these engines are highly sensitive to spark plugs and high-tension leads condition), or all together - but sometimes lean mixture just not fired. "7A-FE LeanBurn - low-speed torque, it is even stronger than 3S-FE because of maximum torque at 2800 rpm" Especial high-torque at low rpm of 7A-FE LeanBurn - one of the common misconceptions. All -FE engines of A series have "two-humped" torque curve - with the first peak at 2500-3000 and the second at 4500-4800 rpm. The height of these peaks is almost the same (difference below 5 Nm), but STD engine have second peak slightly higher, while LB - first peak. But absolute torque maximum of STD is more (157 vs. 155 Nm). Compare with 3S-FE - maximum torque of 7A-FE LB and 3S-FE type'96 is 155/2800 and 186/4400 Nm respectively, 3S-FE at 2800 rpm have torque 168-170 Nm and 155 Nm - already at 1700-1900 rpm.

* Abbreviations and symbols: V - displacement [cm3] N - maximum power [PS / rpm] M - maximum torque [Nm / rpm] CR - compression ratio D×S - cylinder bore × piston stroke [mm] RON - recommended research octane number of gasoline IG - ignition system type VD - collision of the valves and pistons if timing belt broken ** Hereinafter given specs for later engine modifications.

4E-FE, 5E-FE (1989-2002) - basic engines. 5E-FHE (1991-1999) - more powerful version with higher redline and variable intake geometry. 4E-FTE (1989-1999) - turbocharged version that turned Starlet GT in "rabid stool" (local term for small powerful cars). On the one hand, the series have not many critical defects, but on the other hand - rather worse than A series: very weak crankshaft seals, excessive cylinder-piston wear (moreover re-boring was not permitted by manufacturer). And remember that the engine power must conform to the vehicle class - so 4E-FE is appropriate for Tercel but weak for Corolla, and 5E-FE - weak for Caldina. Operating with high load, they have a shorter lifetime and a higher wear against normal engines at the same models.

Note, two actually different engines with the same name existed. First generation - optimal, reliable, unpretentious - produced in 1990-98 (1G-FE type'90). Among the drawbacks - oil pump drive by timing belt (at cold start with frozen oil the belt can jump or teeth cut-off)), weak oil pressure sensor. Overall, it's a good unit, but do not expect outstanding dynamics. In 1998, the engine has been updated radically - with increasing the compression ratio and higher redline output was raised up by 20-hp. The engine was equipped with VVT system, variable intake system (ACIS), direct ignition and throttle valve electronic control (ETCS). The many changes are in the mechanical part - cylinder head construction completely changed, hydraulic belt tensioner appeared, cylinder block, pistons, crankshaft were updated. The parts for 1G-FE type'90 and type'98 are not interchangeable. The valves and piston collision now occurs if timing belt broken. Reliability and service life of the new engine definitely dropped, so legendary indestructibility, easy maintenance and simplicity were lost, and only the same name left.

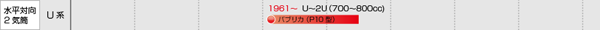

Extremely reliable and archaic (camshaft in the block) design with a good safety factor. The general lack - poor characteristics, corresponding to the time of the first appearance of the series. 5K (1978-2013), 7K (1996-1998) - versions with carburettor. The main and practically the single problem is a too complicated fuel system, so instead of trying to repair or adjust, it is optimal to install a simplest carburetor from older local cars. 7K-E (1998-2007) - later version with fuel injection.

3S-FE (1986-2003) - basic engine of the series - powerful, reliable and unpretentious. Without critical defects, but non ideal - rather noisy, coming-with-age oil consumption, overloaded timing belt (also drives water pump and oil pump), the engine tilted to bulkhead (access to intake manifold and injectors is difficult). Best modifications were produced in 1990-96, but updated version (type'96) was not so trouble-free. Serious defect - connecting rod bolts breaking - see "Toyota 3S engines and broken connecting rod". Repeat once again - never reuse connecting rod bolts of S series engines. Details on the generation difference - " 3S-FE. From dawn to dusk". 4S-FE (1990-2001) - smaller version, completely similar to 3S-FE. Its performance is enough for most models, but not for Mark II family. 3S-GE (1984-2005) - forced engine with "Yamaha cylinder head", available in a variety of versions with different designs for sporty D-class models. It was one of the first Toyota's engine with VVT, and the first with DVVT (Dual VVT). 3S-GTE (1986-2007) - turbocharged version. Some notes for turbo boosted engines: high service cost (the best oil with minimal replacement intervals, best fuel), additional complexity of maintenance and repair, relatively small lifetime. Ceteris paribus remember: even first Japanese buyers took turbo not for shop-riding, so residual durability of the engine and the whole car is unknown, and it more than critical for cars used here. 3S-FSE (1996-2001) - version with direct injection (D-4). The worst Toyota's gasoline engine ever. Irrepressible thirst for perfection transformed good engine into a nightmare. Just never buy cars with this engine. The first problem - the deterioration of the high pressure fuel pump, after which a considerable amount of gasoline gets into the crankcase, cause a catastrophic aftermath to crankshaft and the other elements with sleeve bearings. There are a large carbon deposits in the intake manifold due to the EGR system operation, that affects the engine startability. Above-mentioned "fist of friendship" - standard end of a career for most 3S-FSE (this problem officially recognized by Toyota as safety affecting failure... in April 2012). There are enough problems at other systems of the engine, that have nothing in common with normal S series motors. 5S-FE (1992-2001) - version with increased displacement. As for most gasoline engines larger than 2.0, the Japanese applied the balancer mechanism with gear drive, which slightly affects the overall reliability.

1JZ-GE (1990-2007) - the basic engine for the domestic market. 2JZ-GE (1991-2005) - "worldwide" version. 1JZ-GTE (1990-2006) - the turbocharged version for domestic market. 2JZ-GTE (1991-2005) - "worldwide" turbocharged version. 1JZ-FSE, 2JZ-FSE (2001-2007) - not the best versions with direct injection (D-4). There were no significant defects, the engines are very reliable with proper care (sensitive to wet, so engine washing is not recommended). They are considered as ideal workpieces for various tuning. After modernization in 1995-96 the engines were equipped with VVT and distributorless ignition. It would seem that this is one of rare occasions when motor update did not affect reliability - however, we not only hear but see the problems with piston sticking in cylinders (cause subsequent destruction and the connecting rods bending).

Some details of the design - "MZ series".

3RZ-FE (1995-2003) - the biggest inline-four of Toyota - rather reliable and simple, except too complicated timing drive and balancer shafts drive. The engine was often installed in models of ru-automotive plants (GAZ, UAZ). As for the consumer properties, insufficient thrust-to-weight ratio for heavy models is notable, and its low fuel economy.

2TZ-FE (1990-1999) - the basic engine. 2TZ-FZE (1994-1999) - version with supercharger.

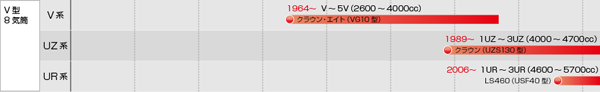

1UZ-FE (1989-2004) - the basic engine, for passenger cars. In 1997 was equipped with variable valve timing and direct ignition. 2UZ-FE (1998-2012) - version for heavy SUVs. In 2004 was equipped with variable valve timing. 3UZ-FE (2001-2010) - replacement of 1UZ for passenger cars.

Versions for FF cars were unreliable and capricious: high fuel consumption, high oil consumption, a tendency to overheat (which usually leads to warping and cracking of cylinder heads), fast wear of the crankshaft main journals, too sophisticated hydraulic fan drive. Also a relative rarity and high cost of spare parts. 5VZ-FE (1995-2004) - installed to HiLux Surf 180-210, LC Prado 90-120, large vans of HiAce SBV family. This engine was quite unpretentious, without many problems of their smaller brothers.

Details of the design and problems - in the large review "Toyota AZ series engines".

Details of the design - in the review "Toyota NZ series engines".

Details of the structure - in the review "Toyota SZ series engines".

Details of the design and problems - see the large review "Toyota ZZ series engines. No room for error". 1ZZ-FE (1998-2007) - basic and most common worldwide engine of series. 2ZZ-GE (1999-2006) - high-forced engine with VVTL (VVT system and valve lift change) and linerless block, which has little in common with the 1ZZ. Unfortunately, this is the most "gentle" and a short-lived forced Toyota's engine. 3ZZ-FE, 4ZZ-FE (1999-2009) - versions for European market. Particular drawback - the lack of Japanese domestic counterpart does not allow the to buy the cheap used engine instead broken one.

Details of the design and modifications - in the review "Toyota AR series engines".

Details of the design and problems - in the review "Toyota GR series engines".

For technical details see the review "Toyota KR series engines".

Details of the design and modifications - in the review "Toyota NR series engines".

1UR-FSE - - the basic engine of the series, for passenger cars, with combined injection (D-4S) and electric drive for intake variable valve timing (VVT-iE) 1UR-FE - with multipoint injection, for cars and SUVs. 2UR-GSE - forced version "with Yamaha cylinder heads", titanium intake valves, D-4S and VVT-iE - for -F models of Lexus. 2UR-FSE - for hybrid systems of the top Lexus - with D-4S and VVT-iE. 3UR-FE - the largest gasoline engine of Toyota for heavy SUVs, with multipoint injection.

Details of the design - "Toyota ZR series engines" and "Valvematic system". Typical defects: increased oil consumption, carbon deposits in the combustion chambers, knock in VVT during starting, water pump leakage, oil leakage from chain cover, alternator pulley break. For Valvematic versions - vacuum pump knocking noise, controller failures, detaching controller from the VM control shaft with subsequent engine stall.

High "geometric" compression ratio, long-stroke, Miller/Atkinson cycle, balancer. The cylinder head: laser-clad valve seats (similar to the ZZ series), straightened intake ports, hydraulic lash adjusters, DVVT (intake - electrically driven VVT-iE), integrated EGR. Fuel system - D-4S (combined injection). Cooling - electric pump (first time for Toyota), electric thermostat. Lubrication - the variable displacement oil pump. Details of the design - "Toyota Dynamic Force engines (R4)".

Details of the design - "Toyota Dynamic Force engines (R4)".

M15A-FKS - in many ways it resembles M20A without one cylinder: D-4, balance shaft, Dual VVT, EGR, electric pump. M15A-FXE - a version for hybrids - with conventional multi-point injection, without balance shaft. Details of the design - "Toyota Dynamic Force engines (R3)".

Details of the design - "Toyota G16E-GTS".

Twin-scroll turbocharger, combined injection D-4ST and vertically mounted high-pressure injectors, united crankshaft case, water control valve... Details about structure - "Toyota engines - T24A-FTS".

Features - long-stroke, DVVT (intake - electrically driven VVT-iE), laser-clad valve seats, twin-turbo (two parallel chargers integrated into the exhaust manifolds, electronically controlled WGT) and two water-air intercoolers, combined injection D-4ST, electric thermostat. Details of the design - "Toyota Dynamic Force engines (V6)".

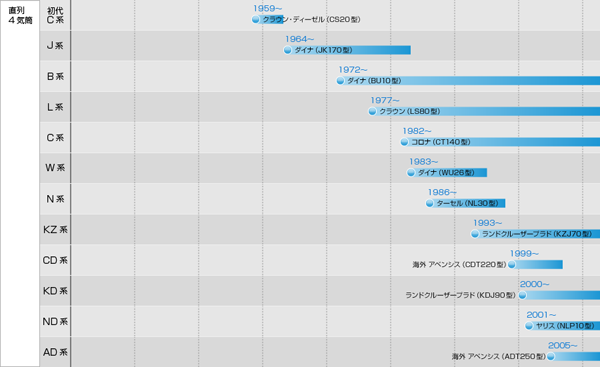

Naturally aspirated versions (2C, 2C-E, 3C-E) as a whole were reliable and unpretentious, but have a very modest performance, in the same time electronically controlled injection pump (-E) required rather qualified technicians for service. Turbocharged versions (2C-T, 2C-TE, 3C-T, 3C-TE) have a high tendency to overheat (following by cracks and warpage of the cylinder head) and the rapid deterioration turbocharger seals. This mainly refers to minibuses and heavy vehicles where work conditions are heavier, and the canonic example of worst diesel - Estima with 3C-T (horizontally installed motor regularly overheates, absolutely not tolerates low quality fuel, and drains out oil through seals at first possibility).

As for reliability, there is complete analogy with C series: relatively successful but low-powered naturally aspirated versions (2L, 3L, 5L-E) and problem turbocharged versions (2L-T, 2L-TE). At turbo versions the cylinder head can be considered as dispensable spare part, that can by damaged even by enough long highway riding.

Low performance (even with turbo) and low margin of safety. Sensitive to the oil viscosity, tendance to the crankshaft damage at cold start. There is not enough technical documentation, so for example correct fuel system adjustment can not be performed, also extremely rare parts.

1HZ (1989-) - due to simple design (cast-iron, SOHC, 2 valves per cylinder, simple injection pump, swirl-chamber, naturally aspirated) and low forcing it was the most reliable Toyota's diesel ever - kind of a legend. 1HD-T (1990-2002) - received the piston-chamber and turbocharging, 1HD-FT (1995-1998) - 4 valves per cylinder (SOHC with rockers), 1HD-FTE (1998-2007) - electronically controlled fuel injection pump.

The design is more complex than L series - belt and gears combination for driving of camshafts, injection pump and balancer mechanism, turbocharging, soon introduced electronically controlled injection pump. However, increased displacement and a significant torque up helped to wast many disadvantages of the predecessor, despite the high cost of spare parts. But the legend of "outstanding reliability" is just a legend formed at the time when quantity of these engines was immeasurably less than quantity of familiar and problematic 2L-T.

1WZ - Peugeot DW8 (SOHC 8V) - simple naturally aspirated diesel with distribution type injection pump. The other engines are turbocharged common rail versions also used by Peugeot / Citroen, Ford, Mazda, Volvo, Fiat... 2WZ-TV - Peugeot DV4 3WZ-TV - Peugeot DV6, versions 95/115 ps 4WZ-FTV, 4WZ-FHV - Peugeot DW10, versions 120/150/180 ps 5WZ-TV, 5WZ-HV - Peugeot DV5, versions 100/120 ps

The level of technology and performance corresponds to 2000s, and in something even inferior than AD series. Light-alloy cylinder block with liners and "closed top", DOHC 16 valve, common rail, electromagnetic injectors (pressure of 160 MPa), VGT, DPF + NSR... The most famous defect of this series - the inherent problems with timing chain, which the Bavarians are trying to solve since 2007. Note. For details see the TSBs related to defective crankshaft pulley (EG-00080T-TME), EGR valve (EG-0024T-0317), timing chain replacement due to high elongation (EG-0004T-0118, 17SMD-115-4)

The design of 3rd wave - "disposable" aluminium cylinder block with liners and "open deck", 4 valves per cylinder (DOHC with hydraulic lash adjusters), timing chain, VGT, balancing mechanism for 2.2. Fuel system - common-rail, injection pressure of 25-167 MPa (1AD-FTV), 25-180 (2AD-FTV), 35-200 MPa (2AD-FHV), forced versions have piezo injectors. Against the competitors AD performance can be called decent, but not outstanding. Severe disease - high oil consumption and the resulting problems with widespread carbon depositions (from clogging intake and EGR to piston deposits and damage to the cylinder head gasket) - the warranty provides for the replacement of pistons, rings and all crankshaft bearings. Also: coolant leakage through the cylinder head gasket, water pump leakage, DPF regenerationsystem failures, destruction of the throttle actuator, oil leakage from the sump, injector amplifier (EDU) defect and injector defects, destruction of the high pressure supply pump components. Details of the design and problems - in the large review "Toyota AD series engines".

Design combined the traditional and new solutions - cast iron cylinder block, timing belt, 4 valves per cylinder (DOHC), VGT. Fuel system - common-rail, injection pressure of 30-135 MPa, solenoid injectors.

More about the design - see review "Toyota GD series engines".

Similar to KZ - cast iron block, gear and belt timing drive, balancer mechanism (1KD), but already VGT used. Fuel system - common-rail, injection pressure of 32-160 MPa (1KD-FTV, 2KD-FTV HI), 30-135 MPa (2KD-FTV LO), solenoid injectors at early versions, piezoelectric at Euro-5. For fifteen years of production the series obsolete - modest performance, poor economy, "tractor"-like comfort level (high vibration and noise). The most serious defect - the destruction of the pistons - is officially recognized by Toyota.

More about the structure, differencies and problems - see review "Toyota diesel - 1ND-TV".

Long-term winner of the competition for the title of the most problematic Toyota engine. Details about the design and typical malfunctions - "1VD-FTV".

More about the structure and features, see review "F33A-FTV".

A small independent cluster - "industrial" engines used for forklifts, construction and agricultural machinery, as well as for stationary machines. In the early 2020s, several low-powered diesel and gasoline/LPG engines are presented, mostly unique, but there are also some from the automotive segment.

1ZS - 3-cylinder diesel, Common-rail, VGT turbocharger, DOC-catalyst. 1DZ - 4-cylinder diesel, swirl chamber. 2Z - 4-cylinder diesel, direct injection. 3Z - 4-cylinder diesel, swirl chamber. 14Z - 6-cylinder diesel, direct injection. 15Z - 6-cylinder diesel, timing gear drive, swirl chamber. 1FS - 4-cylinder gasoline/LPG, EFI, TWC. 4Y - 4-cylinder gasoline, EFI, TWC.

Some explanations to the tables, as well as notes on maintenance would make this article too bulky. Therefore, self-sufficient themes were moved to separate articles. RON General advices and manufacturer's recommendations - "What gasoline to use for Toyota?" Motor oil General advices - "Choosing the motor oil" Spark plugs General notes and the catalog of recommended spark plugs - "Toyota spark plugs" Batteries Some advices and the catalog of recommended batteries - "Toyota. Car batteries" Capacities Reference guide with manufacturer's recommendations - "Fluids and Capacities"

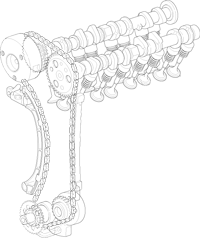

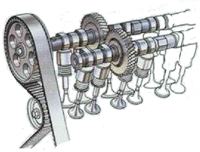

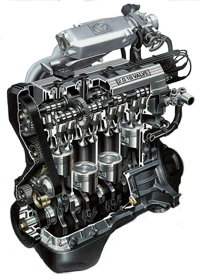

The archaic OHV engines mostly remained in the 1970s, but several of them have been modified and maintained in service until the mid-2000s (series K). Lower camshaft in the block was driven by short chain or gears and moved rods via hydraulic lifters. Today, OHV are using only in the segment of commercial heavy diesel engines. Since the late-1960s SOHC and DOHC engines of different series appeared - with double-row chains, hydraulic lash adjusters or adjusting the valve clearances by washers between the camshaft and the lifters (rare - by screws). The first series with timing belt (A) started in the late 1970s, but by the mid-1980s such engines - what we call "classics" - became the absolute mainstream. Initially SOHC, then DOHC with the letter G in the index - "wide Twincam" where both camshafts driven by belt, then the mass DOHC with the letter F where the belt drives one of camshaft engaged with each other by gear drive. The clearance in DOHC was adjusted by washer over the lifter, but some engines with Yamaha heads maintained washer under the lifter. If the belt is broken, the valves and pistons does not collide, with the exception of forced 4A-GE, 3S-GE, D-4, some V6 and, of course, diesel engines. The consequences for diesels are particularly hard - valve bends, valve guides are broken, often camshaft broken. For gasoline engines also important "chance" - in some engine without initially constructive interference the piston and valves covered with a thick layer of carbon deposits may collide, and contrary, the valves can luckily hang in a neutral position at engine with initial interference. In the early 1990s Toyota's variable valve timing system appeared and since it gone through several stages of development - for more details see large review "Toyota Variable Valve Timing. Evolution" In the late-1990s new engine generation appeared, equipped with chain drive and standard mono-VVT (variable valve timing at intake). Typically, the chain drives both camshafts at inline engines, and at V-engines camshafts were engaged by gear drive or additional short chain. Unlike the older engines, new long roller chains were not so durable. Valve clearance adjusted by tappets of varying heights, that made the procedure too hard, time-stretched, too expensive, and therefore unpopular - the owners stopped to check clearance on the whole. For engines with chain drive the cases of failure are not considered, but in practice when the chain jumped or wrong installed, the valves and pistons usually collide. A peculiar derivation among this generation - forced 2ZZ-GE with variable valve lift height (VVTL-i), but this conception was not developed later. In the mid-2000s, the next generation engines production started. Its main features - Dual-VVT (variable valve timing at intake and exhaust) and revived hydraulic lash adjusters. Another experiment - the second version variable valve lifting - Valvematic at ZR series.

The chain drive advantages: strength and durability - a chain, so to speak, does not break and requires less frequent replacements. The second plus - layout - is only important for the manufacturer: driving of four valves per cylinder, two camshafts with variable valve mechanism, fuel pump, oil pump - require rather wide belt. While installing a thin single-row chain saving a few centimeters of engine length, and at the same time - reduce the transverse dimension and the distance between the camshafts due to traditionally smaller diameter of sprockets in comparison of belt pulleys. Another little plus - the less radial load on the shaft due to the low pre-tensioning force. But not forget the standard drawbacks. - The chain "stretch" during operation (due to wear and backlash of links joints). - To compensate the stretching the pull procedure is required (at some archaic engines) or using of automatic tensioner (which most manufacturers make). Traditional hydraulic belt tensioner works via common lubrication system, which affects its durability (so at the new engines Toyota places it outside the cover, simplifying the replacement). But sometimes the chain stretching exceeds the limit of the tensioner adjustment possibilities, so the consequences for the engine are quite sad. Some third-rate automakers install tensioners without ratchet mechanism, therefore chain chatters during each engine start. - Metallic chain inevitable "saws" slippers, its rollers and sprockets gradually wear, and wear products fall in the engine oil. Even worse that many owners does not replace sprockets and tensioners during chain replacement, although it is obvious that used sprocket quickly ruins a new chain. - Timing chain drive runs noticeably noisier than belt. Among the others, chain speed is uneven (especially if sprocket teeth quantity is small), and when the link engages the impact always occurs. - The chain cost is higher than the timing belt kit (and is simply inadequate sometimes). - Chain replacement is more labor-intensive (the old "mercedes" method is not suitable for Toyota). And the procedure requires accuracy, because valves and pistons collide at chain engines. - At some engines (Daihatsu origin) a toothed chains are used instead roller. These chains are quieter, more precise and more durable, but for unexplained reasons can sometimes jump over sprocket teeth. So, did the maintenance cost reduce after replacement the belts with the chains? The chain drive requires an interventions as often as belt drive - firstly hydraulic tensioner, then stretched chain (on average 150.000 km)... and total cost is higher, especially if do not save every cent and replace all the necessary components simultaneously. The chain is good - if two-row, if engine have 6-8 cylinders, and if there is a three-beam star on the engine cover. But belt timing drive of classic Toyota engines was so good and reliable, that long thin chains became step backwards.

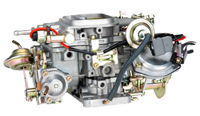

In the post-soviet space primitive carburetor system of locally produced cars will never have competitors for maintainability and cheapness. All electronics - override-idle valve, all vacuum - ignition timing regulator and crankcase ventilation, all kinematics - throttle, manual choke and the drive of the second chamber (Solex). Relatively simple and understandable. A cheap cost allows literally carry in the trunk a full replacement kit for fuel and ignition systems, but technicians and spare parts can always be found somewhere nearby. Toyota carburetor - is another matter. Just look at 13T-U of late 1970s - a real monster with many tentacles of vacuum hoses... But later "electronic" carbs were extremely complicated - catalyst, oxygen sensor, air bypass to exhaust, exhaust gas recirculation, electrical choke, two or three stages of idle control by load, 5-6 vacuum actuators and two-stage dampers, fuel tank and the float chamber ventilation, 3-4 VSV, thermo valves, override-idle valve, ignition adjusting, air heating system, a set of sensors (coolant temperature, intake air temperature, speed, knock, throttle switch), electronic control unit... Why did they need such difficulties if normal MFI modifications already exist - who knows, but in any case such systems, tied to a vacuum, electronics and kinematics, worked at a very delicate balance. And debalanced easily - by age and dirt as any carburetor. Sometimes it was even dumber - impulsive mechanic disconnected all multiple hoses, but not remembered where to reconnect it properly. It is possible to revive this carb anyhow, but to adjust (allow at the same time to maintain a normal cold start, normal warming, normal idling, normal load adaptation, normal fuel consumption) - is extremely difficult. As might guess, a few carburettor guru with knowledge of the Japanese specifics lived at far-east region, but twenty years later even the locals forgot their names. As a result, Toyota's fuel injection was rather simpler than later carburettors - there were not much more electrics and electronics, but less vacuum and no complicated kinematics - which gave us such a valuable reliability and maintainability.

The most foolish argument - "direct injection will soon wast traditional". Even if it were true, it does not mean that direct injection engines have not alternative now. For a long time term "D-4" means a specific engine - 3S-FSE. But it was installed at 1996-2001 in three models for the domestic market, and in each case, classic 3S-FE was as alternative. Later choose between the D-4 and the normal injection usually saved... Since the second half of the 2000s Toyota refused to use the direct injection at the mass segment and returned to this theme after ten years (see also "Toyota D4 - perspectives?"). "The engine is excellent, we just have gasoline (nature, people ...) bad" - this is again scholasticism. Let this engine is good for the Japanese, but what is the use of it here? - the country of poor gasoline, harsh climate and imperfect people. So instead of the mythical advantages of D-4 only its drawbacks emerge. Appeal to foreign experience "but in Japan, in Europe" is not conscientious. The Japanese are deeply concerned about the far-fetched problem of CO2, the Europeans - the reduction of emissions and fuel efficiency. But here the living standard still forces us to solve real basic problems and not to fantasize about fictitious problems. Stories that "D-4 engine fuel consumption is three liters less" - just unpretentious misinformation. Even the passport maximum economy of the new 3S-FSE compared to the new 3S-FE on one model was 1.7 l / 100 km - and it's in the Japanese test cycle (so the real economy always was less). During active city driving D-4 operates at power mode, without consumption reducing. The same when highway driving - D-4 high efficiency area (speed/rpm) is narrow. And indeed, it is incorrect to talk about consumption relatively used car - it is much more dependent on the technical condition of a specific car and driving style. Experience shows that some of the 3S-FSE, conversely, consume more gasoline than 3S-FE. Often says "change the fuel pump and no problems". But regularly replacement of the main part of fuel system at relatively fresh Japanese cars (especially Toyota) - it's just nonsense. And it was not the best way to waste $300 every ~30-50.000 km. Nobody said that the fuel injectors, which are also often required replacement, cost comparable to pump. Of course, they ignored standard and fatal mechanical problems of 3S-FSE. Perhaps not everyone think about the fact that if the engine has "caught the twice oil level in the sump", it already worked with gasoline-oil emulsion instead oil that affects all the moving parts of the engine (do not juggle comparing several grams of gasoline falling in the oil during a cold start and evaporates with the heating of the engine, and constantly flow into the crankcase liters of fuel through wear D-4 pump). Nobody warned not try to "clean the throttle" - properly adjusting of the engine management system required special equipment. Not everyone knows how EGR system poisoned the engine with exhaust gas and how carbon accumulates in intake, that required regular disassembly and cleaning (approximately every 20-30.000 km). Not everyone knows that any attempt to replace the timing belt "similar to the 3S-FE" often lead to a pistons and valves collision. Not everyone knows whether there is in their city at least one garage, successfully solves the problem of D-4. And why exactly Toyota valued here? (While there are cheaper, faster, sports, comfortable japanese cars? For "simplicity", in the broadest sense of the word. Simplicity in operation conditions, fuel, parts, repair... Yeah, can buy high-tech scrap for the price of a normal car. Can look for good gasoline and add some chemicals. It is possible to count every cent saved on gasoline - for upcoming repair. Can teach local technicians the basics of direct injection systems. Can re-adopt "for a long time car did not break, when at last will fall?" There is only one question - "What for?" After all, consumer's choice - their private affair. The more people will contact D-4 and other dubious technologies - the more clients repair shops will have. But decency requires to say - buying old car with D-4 if any alternative exists - is contrary to common sense..

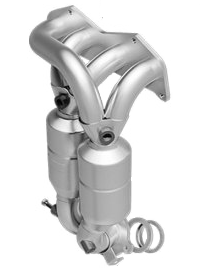

Retrospective experience allows to be firmly convinced - a necessary and sufficient level of emission reduction was already provided at classic models in the Japanese market in the 1990s, or by Euro II standard in the European market. This required multipoint injection, one oxygen sensor and catalytic converter under the floor. Such cars operates for many years in the standard configuration, despite the hideous quality of gasoline, age and mileage (sometimes oxygen sensors required replacement); the catalyst could be removed without any problems - but usually there was no such need. The problems began at Euro III stage and correlating rules for other markets, and then just expanded - the second oxygen sensor, catalyst moved closer to the exhaust, cat-manifold appeared, wide-range mixture sensors, electronic throttle control (more accurate - algorithms deliberately worsening the engine response to the accelerator), increasing operation temperature, broken ceramic fragments of converters in the cylinders... Today, with in the normal gasoline quality and much more younger vehicles, the removal of catalysts and ECU reprogramming Euro V> II is popular massive work. If the older cars can be equipped with affordable universal catalytic, the freshest and "intelligent" cars have no other alternative than cat-manifold punching and re-programming to disable emission control. A few words on some "environmental" excesses (for gasoline engines): - Exhaust gas recirculation (EGR) - an absolute evil, as soon as possible it should be plugged (taking into account the specific design and the feedback control), to stop the engine poisoning and contamination of its own waste. - Fuel vapour absorbing system (EVAP) - at cars for Japanese and European markets works normally, so the problems arise only at models for US market due to complexity and "sensitivity." - Air injection to exhaust (SAI) - unnecessary, but relatively innocuous system for North American models.

In fact, the recipe of abstract best engine is simple - gasoline, R6 or the V8, naturally aspirated, cast iron block, the maximum margin of safety, the maximum displacement, multipoint injection, the minimum forcing... alas, in Japan such engines installed only in top-class. The compromises are inevitable in affordable for the mass consumers market segments, so the motors can be not the best here, but at least "good". The next task - to assess the motors with regard to their actual use - providing a thrust-weight ratio acceptable, in which trims used (ideal for compact models engine is clearly insufficient in the middle class, a better design engine can be not aggregated with all-wheel drive, etc.). And finally, the time factor - our regrets about the excellent engines, which have been taken out of production for 15-20 years ago, do not mean that it is good idea to buy the worn-out cars with these engines today. So it makes sense to talk about the best engine in its class and its time interval. 1990s. Among the classic engine it is easier to find a few bad than to choose the best of the good. However, two absolute leader are well known - 4A-FE STD type'90 in a light class and 3S-FE type'90 in medium. In a top class 1JZ-GE and 1G-FE type'90 are equally commendable. 2000s. As for the engines of the third wave, the good words exist only for 1NZ-FE type'99 in light class; the rest of this series are competing for an outsider rank; so there are not even "good" engines in medium class. In top class note 1MZ-FE, which is against the background of the young competitors turned out not bad. 2010s. The circumstances have changed a bit - at least, 4th wave engines look better than its predecessors. In the light class 1NZ-FE still presented (unfortunately, in most cases it is "worse-upgraded" type'03). At the high segment of medium class 2AR-FE seems not bad. As for top class, due to known economic and political reasons it no longer exists for mass consumer.

However, it is better to see how newer engines worsened on the examples. About 1G-FE types '90 and '98 mentioned above, and what the difference between a legendary 3S-FE types '90 and '96? All of deterioration caused by the same "good intentions", like reducing mechanical losses, fuel consumption, CO2 emissions. The third point relates to the completely insane (but profitable for some) the idea of the mythical struggle against the mythical global warming; and the positive effects of the first two turned out to be a disproportionately smaller than negative... Deterioration in mechanical associated with piston group. It would seem that the new pistons with cut (T-shaped) skirts to reduce friction losses could be welcome? But in practice such pistons knocking at TDC at much smaller mileage than a classic type'90. And the sound means not only noise but increased wear. The absolute stupidity is replacement of full floating piston pins by pressed in rod head. Replacing of distributor by DIS-2 may be positive - no rotating mechanical parts, longer service life of the coils, higher ignition stability... And in reality? It is clear that it is impossible to manually adjust the basic ignition timing. But new ignition coils life time drops in comparison with classical. High-voltage wires life time reduced (now every plug sparks twice for a cycle) - instead of 8-10 years to 4-6 only. Well, at least standard plugs remained simple double-electroded, not platinum. Because of the same "ecology" catalytic converter moved from the underfloor to the exhaust manifold in order to warm up faster. The result - overheating of the engine compartment, reducing cooling system efficiency. About the notorious consequences of possible contamination of cylinders with damaged converter particles - there's no need to talk. Fuel injection - sequential instead paired or synchronous (once per cycle for each cylinder). In fact, the gasoline before entering the cylinder was now given much less time for evaporation, thus automatically worsened starting at low temperatures.

Can only talk about the life time before major repair, when the mass series engine, such as A or S, required the first serious overhaul (except timing belt replacement). For most classic engines it is about 200-250.000 km. As a rule, repair procedure includes replacement of the worn out or stuck piston rings and valve stem seals, but not cylinders reboring (geometry and hone on the walls usually stored). Next-generation engines usually require the attention at the second hundred km mileage, and in best case piston and rings replacing is enough (it is desirable to change the parts with modified according to the latest service bulletins). If high oil consumption and excessive noise of pistons present at mileage over 200.000 km - should be prepared for a large repair - liners wearing leaves no other options. Toyota does not provide reboring of alloy cylinder blocks, but in practice, block liners replacement and boring is possible. Unfortunately, reliable companies who perform high-quality repair of modern "disposable" motors can be really counted on the fingers of one hand. But the cheerful reports about successful liners replacement already come from village workshops and garage - what to say about the work quality and such engine durability? - understandably.

This question is wrong, as in the case of "absolutely the best engine". Yeah, the modern engines are not comparable with the classic ones for reliability, durability and survivability. Their mechanical is much less repairable, they are too complicated for unskilled service... But the fact - no longer an alternative exists. New engines should be seen as a reality and it is need to re-learn to work with them. Of course, car owners should avoid specific bad engines and unsuccessful series. Avoid the early version of every new engine until Toyota fix its "childhood" diseases. If there are several modifications of specific model - should always choose a more reliable - even compromising or financial, or in performance. P.S. In conclusion - must to thank Toyota for that once they produced real "peoples" engines, a simple and reliable, without many complications inherent to other brands. And let the owners of "innovative and advanced" cars call them "old-fashioned coarse" - it is a compliment!

Our articles about Toyota engines

• AD diesel |

|