|

Eugenio,77

mail@toyota-club.net

© Toyota-Club.Net

Jul 2005 - Nov 2013

NZ can be considered the most long-lived of the current series. Introduced first in 1997, it used for new models even in mid-2010's. This review, beside AZ and ZZ ones, will be boring - but it's one of the main series advantages.

| Engine |

Displacement, cm3 |

Bore x Stroke, mm |

Compression ratio |

Output, PS |

Torque, Nm |

RON |

Standard |

Model |

Year |

| 1NZ-FE | 1496 | 75.0 x 84.7 |

10.5 | 105 / 6000 | 138 / 4200 | 91 | JIS | NZE124 | 2000 |

| 10.5 | 110 / 6000 | 140 / 4400 | 91 | JIS | NZT260 | 2007 |

| 10.5 | 109 / 6000 | 141 / 4200 | 91 | SAE | NCP90 | 2005 |

| 11.0 | 109 / 6000 | 136 / 4800 | 91 | JIS | NZT260 | 2013 |

| 2NZ-FE | 1298 | 75.0 x 73.5 |

10.5 | 88 / 6000 | 121 / 4400 | 91 | JIS | NCP15 | 1999 |

| 10.5 | 87 / 6000 | 120 / 4400 | 91 | JIS | NCP95 | 2009 |

| 10.5 | 82 / 6000 | 119 / 4400 | 91 | SAE | NCP90 | 2005 |

| 10.5 | 86 / 6000 | 121 / 4400 | 91 | SAE | NCP90 | 2005 |

| 1NZ-FXE | 1496 | 75.0 x 84.7 |

13.5 | 58 / 4000 | 102 / 4000 | 91 | JIS | NHW10 | 1997 |

| 13.0 | 72 / 4500 | 115 / 4200 | 91 | JIS | NHW11 | 2000 |

| 13.0 | 70 / 4500 | 111 / 4200 | 91 | SAE | NHW11 | 2001 |

| 13.4 | 74 / 4800 | 111 / 3600 | 91 | JIS | NHP10 | 2012 |

1NZ-FE type'99 (1.5 EFI VVT) - transverse, with traditional multipoint injection, for initially FF cars. Note - the models initially received type'99, was equipped with it until production end, even after appearing of type'03 (exception - Corolla NZE121). Installed in: Allion/Premio 240, Bb 30, Corolla/Fielder/Runx/Allex 120, Corolla Spacio 120, Funcargo, Ist 60, Platz, Porte 10, Probox/Succeed, Ractis 100 (4WD), Raum 20, Scion xA 60, Scion xB 30, Sienta (4WD), Vios 150, Vitz 10, Will Cypha, Will VS, Yaris/Echo 10, Yaris 90..130..150, Yaris Verso 20.

1NZ-FE type'03 (1.5 EFI VVT). Installed in: Allion/Premio 260, Auris 150..180 Jap, Corolla 120..140..160, Corolla Rumion 150, Ist 110, Porte 140, Ractis 100(2WD)..120, Sienta (2WD), Vitz 90..130.

1NZ-FXE (1.5 EFI VVT) - for hybrid cars. Installed in: Aqua 10, Prius 10..20, Prius C, Yaris Hybrid 130.

2NZ-FE (1.3 EFI VVT). Installed in: Bb 30, Belta, Corolla 120, Funcargo, Ist 60, Probox/Succeed, Vios 90..150, Vitz 10..90, Will Cypha, Yaris 10..90..130..150.

Oddly enough, but the first in NZ series was the specific "hybrid" modification, which had quite a few differences from the followed traditional versions - from "Atkinson cycle" and compression ratio to initially implemented ETCS. 1NZ-FXE could be called - the first engine of "third wave", the first mass engine with chain timing drive (after a long pause), the first engine with modern VVT... However, we will not change out principle in relation to the hybrids - "aut nihil".

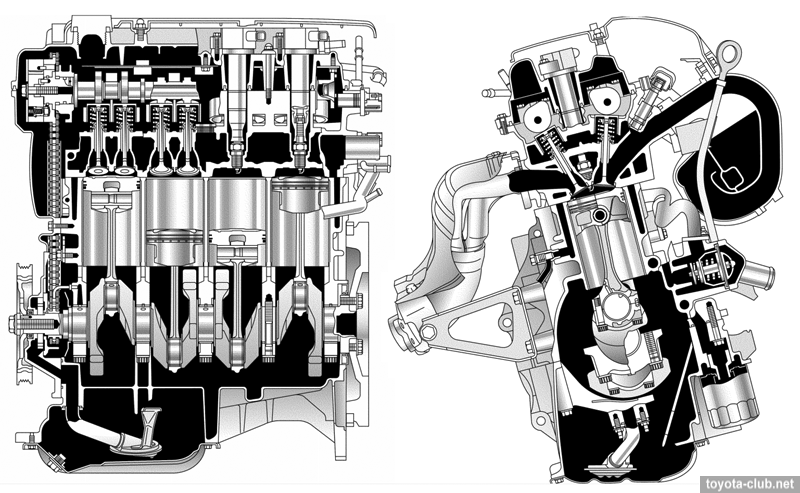

| 1NZ-FE (1.5 EFI) type'99 / 2NZ-FE (1.3 EFI) |

Engine mechanical

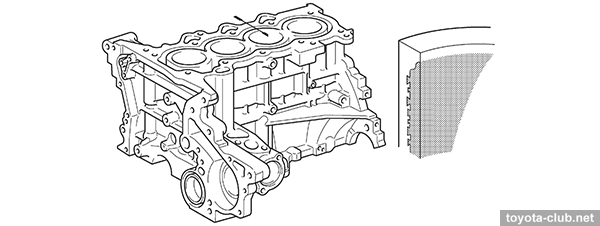

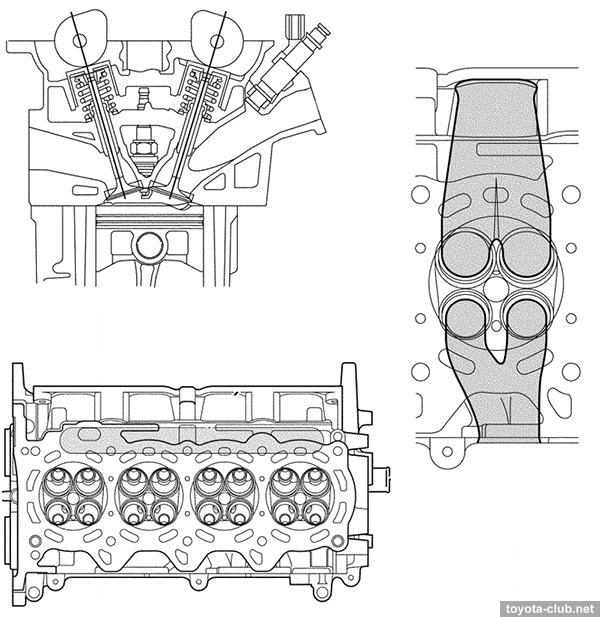

The cylinder block - aluminum "open deck" with thin cast iron liners. The liners are fused into block and their special rough outer surface promotes strong connection. Of course, no overhaul with reboring provided. The massive alloy crankcase mounted to block also performs the function of the sump upper part.

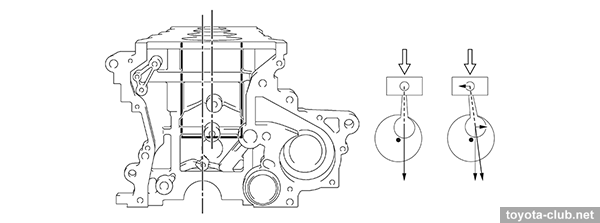

Forged steel crankshaft with 5 journals and 4 balance weights is held by individual main bearing caps. The axis of the crankshaft has been shifted by 12 mm relative to the cylinder axis lines ("desaxage"), thus reducing the lateral component of the force exerted by the piston to the cylinder wall, reducing wear.

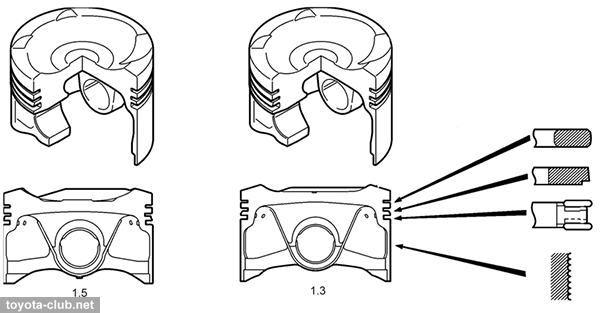

Pistons - aluminum, moderately cut skirt with a friction reducing polymer coating (LFA - Low Friction Resin with Alumina). Disadvantage - press-fit piston pins, not full-floating type, although in practice it is still not caused real problems.

Cylinder head of traditional design, with standard valve seats and holes for injectors.

Timing drive - 16-valve DOHC, driven by single-row roller chain (pitch 8 mm), with hydraulic tensioner (with ratchet mechanism) and lubricated by separate oil nozzle. The valve clearance is adjusted by a set of tappets, without adjusting washers or lash adjusters.

There is VVT (variable valve timing system) sprocket on the inlet camshaft, the range - 40°.

For some regions specific modifications of 2NZ-FE was produced - for leaded gasoline, without VVT, without converter and relative components.

Lubrication system

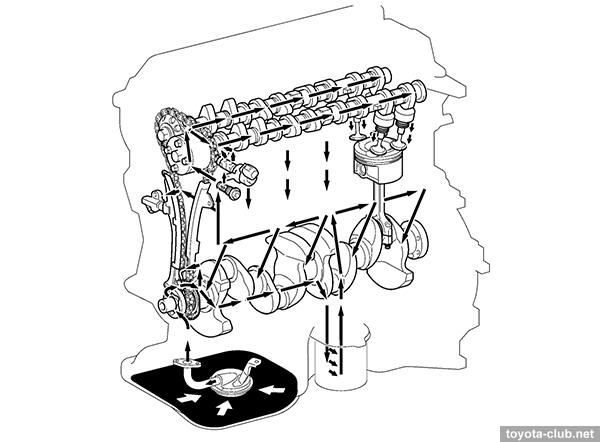

Trochoid oil pump in chain cover is driven directly by the crankshaft. The oil filter is located vertically under the engine.

Cooling system

Система охлаждения кл

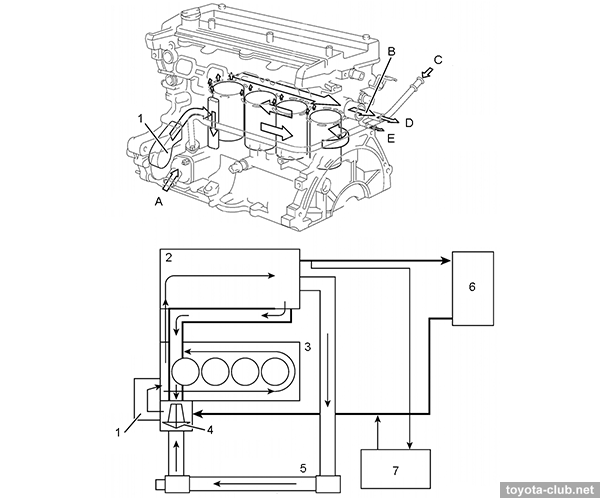

The cooling system is classic for the 3rd wave engine: pump drive by serpentine belt, "cold" (80-84°C) mechanical thermostat, heated throttle body.

1 - water pump, 2 - cylinder head, 3 - cylinder block 4 - thermostat, 5 - radiator, 6 - heater, 7 - throttle body. A - from radiator, B - to radiator, C - from heater, D - to heater, E - to throttle body.

|

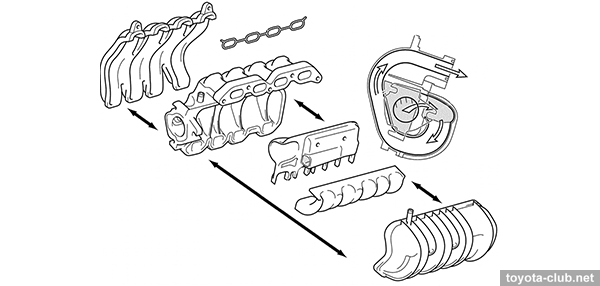

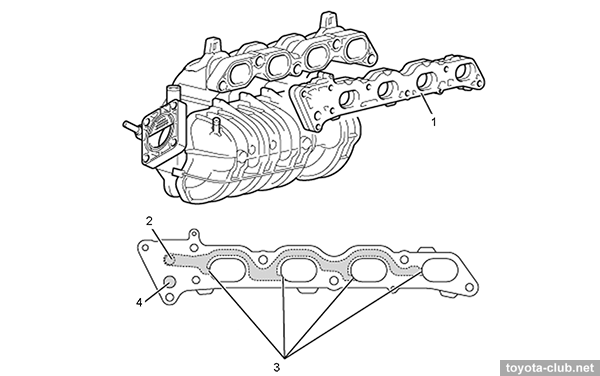

Intake and exhaust

New manifolds location: plastic (to reduce the weight and reduce heating of the inlet air) intake - front, outlet - behind.

Fuel injection system

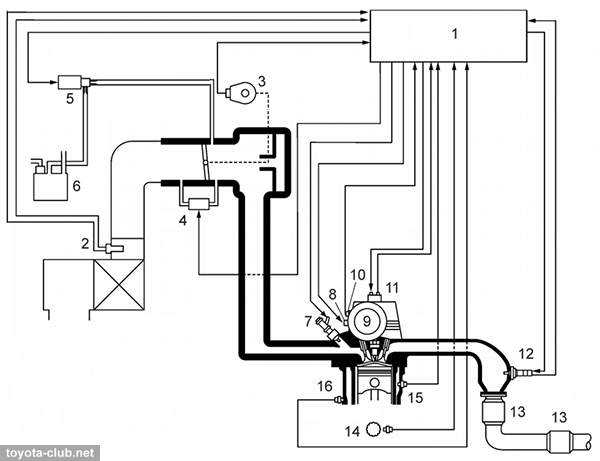

The control system - "L-type SFI", with mass air flow sensor (MAF) "hot wire" type, combined with intake air temperature sensor.

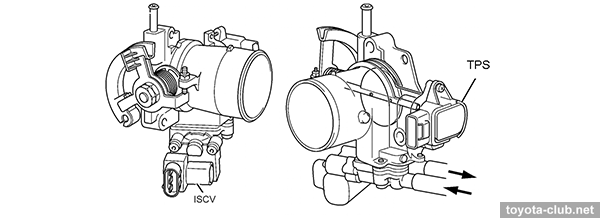

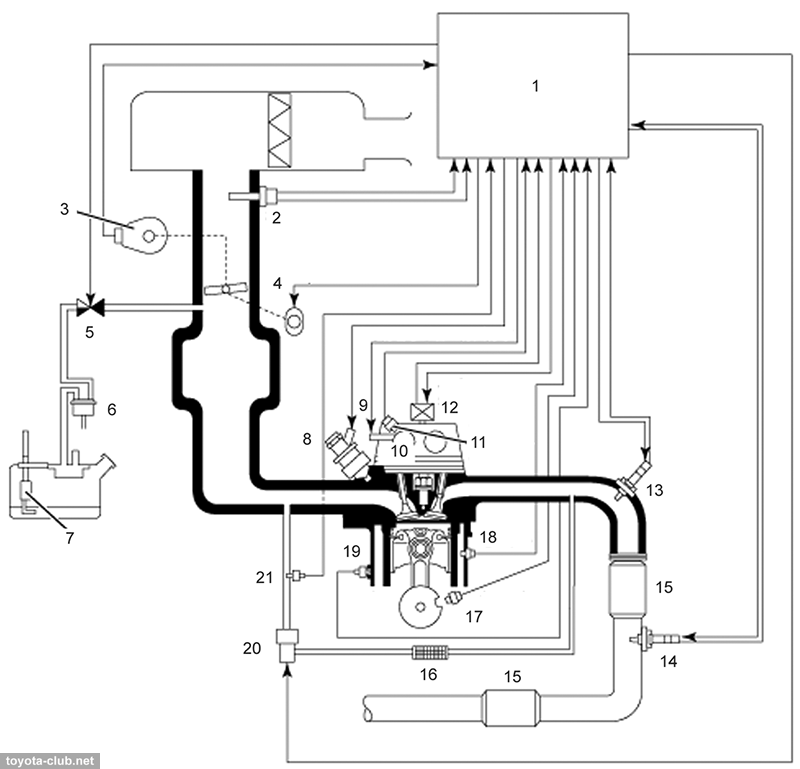

1 - ECM, 2 - MAF sensor / intake air temperature sensor, 3 - throttle position sensor, 4 - ISCV valve, 5 - EVAP valve, 6 - absorber, 7 - injector, 8 - VVT valve, 9 - VVT actuator, 10 - camshaft position sensor, 11 - ignition coil, 12 - oxygen sensor, 13 - catalyst, 14 - crankshaft position sensor, 15 - coolant temperature sensor, 16 - knock sensor.

|

Fuel injection - traditional multipoint, sequential under normal conditions. In some conditions (low temperature and low speed) paired injection can be performed. In addition, injection can be also performed synchronized (once per cycle at the same position of the crankshaft, with managed time of injection) or unsynchronized (by all injectors simultaneously).

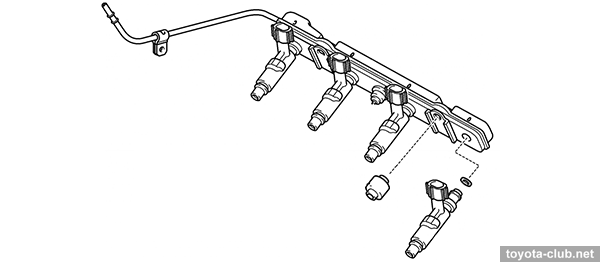

Fuel system - without a return line, with the pressure regulator and the fuel filter built in pump module, the fuel pressure - about 325 kPa. Pulsation damper mounted on fuel rail.

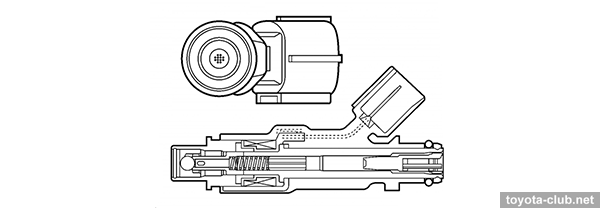

The injectors with multi-hole nozzl are used to improve dispersion of fuel.

Throttle drive - mechanical, idle speed control - classic "rotary solenoid".

Oxygen sensor (89465) installation variants - upstream catalyst (domestic market) or upstream and downstream catalyst (overseas markets).

Ignition system - DIS-4 (separate coil with integrated igniter for each cylinder). Spark plugs - ordinary (Denso K16R-U11, NGK BKR5EYA11).

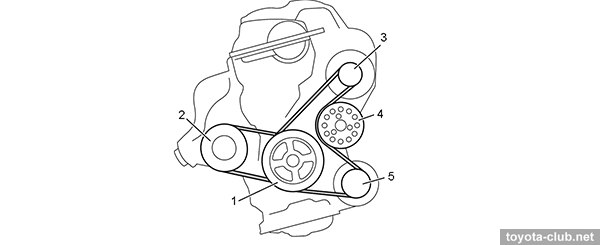

Auxiliary drive - by single serpentine belt, without tensioner (tension adjusting - by alternator moving).

1 - crankshaft 2 - power steering pump, 3 - alternator, 4 - water pump, 5 - compressor.

|

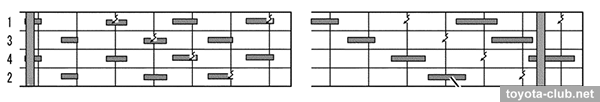

Type '99/05

Since the beginning of 2005 for overseas market models new modification was introduced, which had some differences (mainly on the control system).

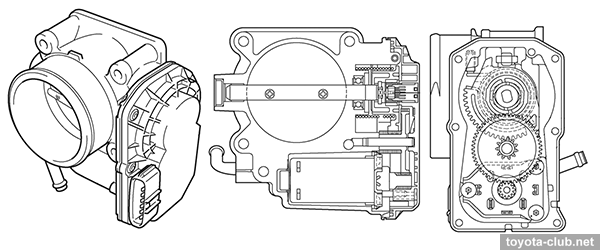

- Throttle valve - fully electronically controlled (ETCS): DC motor, dual-channel contactless position sensor (Hall effect), separate accelerator pedal position sensor. ETCS performs some functions of traction control (TRC) and, on later models, stabilization (VSC).

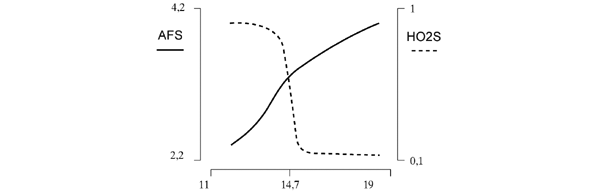

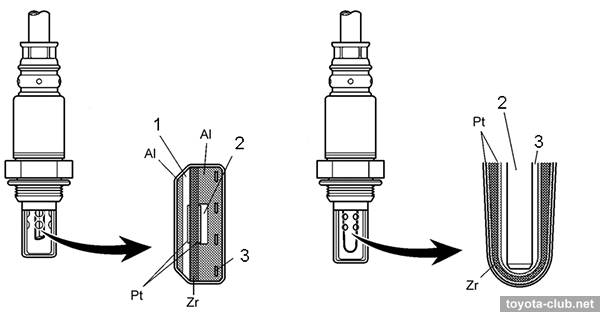

- Air-fuel ratio (AFS) sensor (89467) upstream catalyst and oxygen sensor (89465) downstream (European and North American markets).

1 - expander, 2 - ambient air, 3 - heater.

|

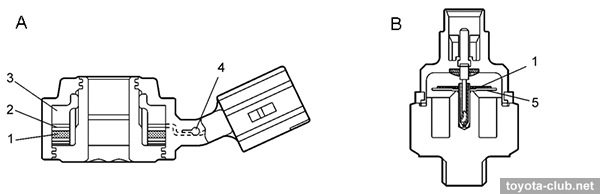

- "Flat" piezoelectric knock sensor was introduced, unlike the old type of resonant knock sensors it feels a wider range of vibration frequencies.

1 - piezo, 2 - insulator, 3 - steel weight, 4 - control resistor, 5 - vibroplate. A - "flat" type, B - resonance type.

|

- Spark plugs with "iridium" center electrode (Denso SK16R11).

Type '99/10

In 2010, after JC08 emission standards implementation, version for domestic market was slightly modified - it has received the AFS sensor, flat knock sensor, iridium spark plugs, but still kept the mechanical throttle drive.

| 1NZ-FE (1.5 EFI) type '03 |

Domestic market models appeared after second half of 2003 (except Porte 10, 4WD Sienta & Ractis 100) was equipped with seriously modified engine.

- There are hydraulic lash adjusters and roller rockers in the valve mechanism. Significantly (from 33 to 21°) reduced angle between valves.

- In the lubrication system new oil path was provided - oil supply to lash adjusters and rockers.

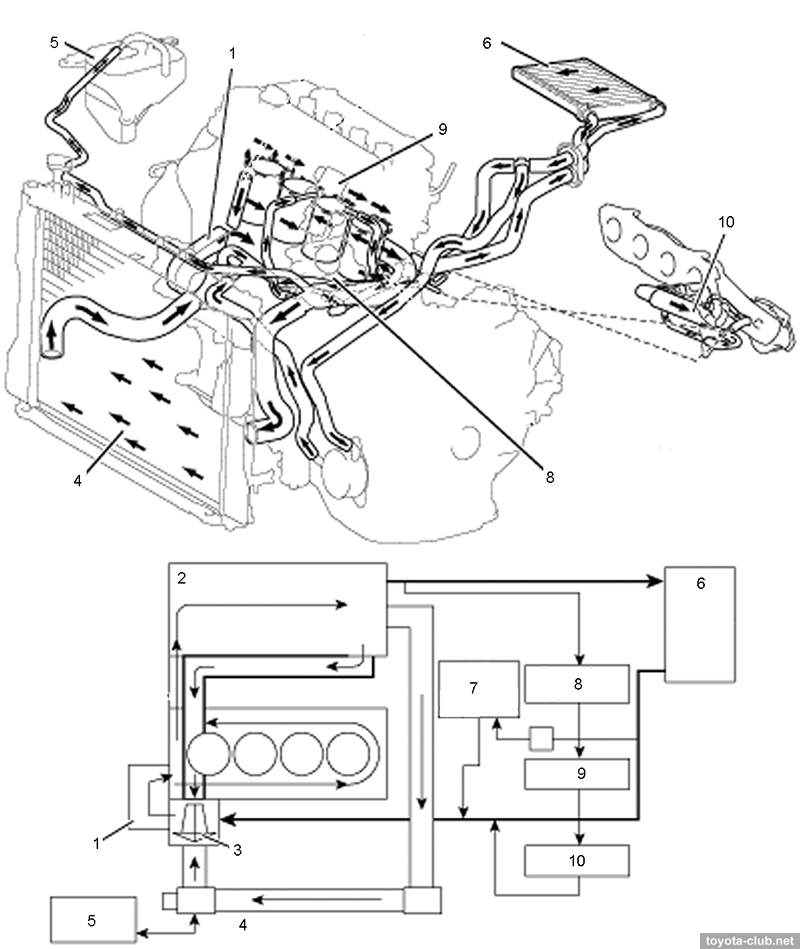

- The cooling system was added with transmission fluid heater (for CVT) and EGR cooler. More "hot" (88°C) thermostat was applied.

1 - water pump, 2 - cylinder head, 3 - thermostat 4 - radiator, 5 - coolant tank, 6 - heater, 7 - CVT fluid heater, 8 - throttle body, 9 - EGR valve, 10 - EGR cooler.

|

- All engines was equipped with ETCS, EGR and electronically controlled fan, new models launched since 2005 was received with AFS sensor and flat knock sensor. The fuel rail serves as a pressure pulsation damper. Spark plugs - "iridium", with a long threaded portion (Denso FK20HR11, NGK ILFR6D11).

1 - ECM, 2 - MAF sensor / intake air temperature sensor, 3 - throttle position sensor, 4 - ETCS, 5 - EVAP valve, 6 - absorber, 7 - fuel pump, 8 - injector, 9 - VVT valve, 10 - VVT actuator, 11 - camshaft position sensor, 12 - ignition coil, 13 - AFS sensor, 14 - oxygen sensor, 15 - catalyst, 16 - EGR cooler, 17 - crankshaft position sensor, 18 - coolant temperature sensor, 19 - knock sensor, 20 - EGR valve, 21 - EGR temperature sensor.

|

EGR system. System is used to reduce combustion temperature, decrease content of nitrogen oxides in the exhaust gases, reduce pumping losses at the inlet.

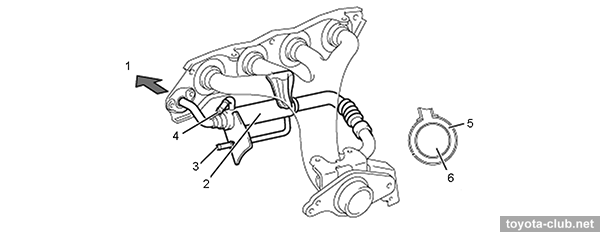

1 - EGR valve, 2 - EGR cooler, 3 - water inlet, 4 - water outlet, 5 - water, 6 - exhaust gas.

|

Exhaust gases from the exhaust manifold pass through a cooler and via channel in the cylinder head flows to the valve. EGR valve is driven by a stepper motor.

1 - EGR valve, 2 - EGR temperature sensor, 3 - actuator, 4 - water, 5 - spring, 6 - valve, 7 - exhaust gas.

|

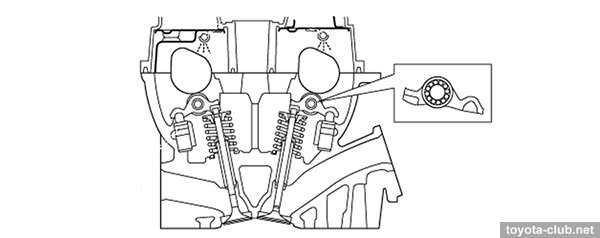

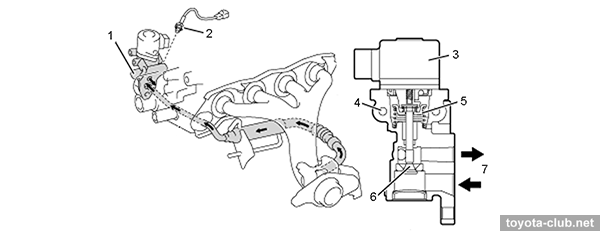

Exhaust gases from the valve flows into EGR manifold, which uniforms stream of gases in each cylinder.

1 - EGR manifold, 2 - from EGR valve, 3 - EGR inlet, 4 - gas inlet.

|

This "well-forgotten old" solution was serious deterioration for 1NZ-FE. Technology of engine self-poisoning by exhaust gas and soot deposits in the intake - is unambiguous evil, especially for small-displacement gasoline engine. At the first opportunity in almost any car EGR line should be plugged, but in this case simple solution will not work - Toyota provided the system operation control by EGR temperature sensor.

Against the background of modern Toyota's engines NZ series can be considered successful and devoided of specific critical defects (such as AZ "drop-head" or ZZ chronic oil burning).

• Quite common problem - unstable or too low idle speed, sometimes supplemented by power loss at medium speed. There are not definite cause and universal solution, but these engines like cleanness - washing of the throttle body, ISCV, MAF-sensor, PCV valve may have an effect. However, the owners overly fixated on the washing, forgetting that sometimes ISCV, MAF, ignition coil or VVT actuator just have to be changed.

• Increased oil consumption for NZ - a purely age-related phenomenon. As for classic Toyota engines, it appears after ~150.000 km and is moderate (200-300 ml / 1000 km), increase during long rides with high rpm. Overhaul with replacement of piston rings and valve seals makes sense in case of indecent oil burning (500 ml).

• More often oil leaks or "sweating" occur, which do not impact the oil level - from under the chain cover, chain tensioner, seals (subjectively - too often rear crankshaft oil seal leaks). Strange related defect - oil leaks inside the crankshaft position sensor and then to sensor connector cause signal missing (recall issued for early 2000s engines).

• Also age-related common Toyota's disease of VVT actuator rattle after a cold start. Note, early actuator modification (13050-21040) was recognized as subject to replacement by modified (-21041).

• Some attention should be paid to lubrication system cleanness, especially VVT lines including the notorious additional filter.

• Finally, do not forget about the limited life time of timing chain - informal, as the critical value can be considered 150.000 km. Together with chain replacement it would be appropriate also replace other components (sprockets, tensioner, guides).

Another note is not directly related to the design features of these motors. Gradually increasing weight of cars (the influence of passive safety requirements and expanding standard equipment list), increasing pressure of emission standards, significantly changed the unspoken standards of thrust-weight ratio... And once conditionally tolerant specs of 2NZ-FE does not correspond to modern requirements for power and torque, while 1NZ-FE specs can be considered normal only for light-weight B-class cars. However, even for C-class or domestic D-class these engines can no longer provide adequate dynamics.

Well, all those for whom 1NZ-FE power is enough, can be satisfied - they have one of so rare successful modern engines under the hood.

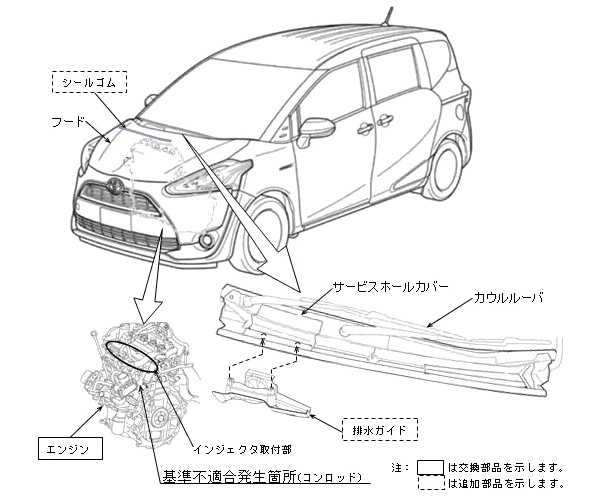

• Recall 5131 (14.04.2022) Big repeated recall for all hybrid Sienta NHP170 with 1NZ-FXE 2015-2022. Problem: the waterproof of the cowl deteriorates, rainwater flows onto the engine and penetrates through the injector mountings into the intake and further into the combustion chambers; there is a possibility of hydraulic shock and the connecting rod damage. Prescription: revision of the cowl drainage and hood seals; inspection of the combustion chambers; replacement of the engine if necessary.

|

Toyota engines review

·

AZ ·

MZ ·

NZ ·

SZ ·

ZZ ·

AR ·

GR ·

KR ·

NR ·

ZR ·

AD ·

GD ·

ND ·

VD ·

A25.M20 ·

F33 ·

G16 ·

M15 ·

V35 ·

|

|

|