|

Eugenio,77

mail@toyota-club.net

© Toyota-Club.Net

Oct 2019 - Feb 2022

| Engine | Displacement, cm3 | Bore x Stroke, mm | Compression ratio | Output, PS | Torque, Nm | RON | ECS |

| 1KR-FE | 998 | 71.0 x 84.0 | 10.5 | 71 / 6000 | 94 / 3600 | 91 (JIS) | EFI VVT |

| 1KR-FE | 998 | 71.0 x 84.0 | 10.5..12.5 | 69 / 6000 | 92 / 3600 | 91 (JIS) | EFI VVT |

| 1KR-FE | 998 | 71.0 x 84.0 | 10.5..11.5 | 69 / 6000 | 91-95 / 4500 | 95 (EEC) | EFI VVT |

| 1KR-FE | 998 | 71.0 x 84.0 | 11.8 | 72 / 6000 | 93 / 4400 | 95 (EEC) | EFI DVVT |

| 1KR-DE | 998 | 71.0 x 84.0 | 10.5-11.1 | 57-66 / 5000-6000 | 85-90 / 3600-4000 | 91 | EFI |

| 1KR-VE | 998 | 71.0 x 84.0 | 11.5 | 66-68 / 6000 | 89-91 / 4400 | 91 (JIS) | EFI VVT |

| 1KR-VET | 998 | 71.0 x 84.0 | 9.5 | 98 / 6000 | 140 / 2400-4400 | 91 (JIS) | EFI VVT |

* weight of 1KR-FE - 67..70 kg (dry weight without alternator, starter, compressor).

A series of 3-cylinder engines designed by Daihatsu, in production since 2004. Replacement of EJ-VE/DE and 1SZ-FE. All KR engines can be considered as different modifications of the one engine, those are produced at the same time for different brands and models.

Applications:

1KR-FE - Toyota Aygo 10..40, iQ, Yaris 90..130, Vitz 90..130, Passo 10..30..700, Tank/Roomy, Belta; Daihatsu Thor, Boon 300..600.700, Charade 90, Sirion, Cuore; Subaru Justy; Peugeot 107..108; Citroen C1

1KR-DE - Toyota Agya/Wigo; Daihatsu Ayla, Himax; Perodua Axia

1KR-VE - Toyota Agya/Wigo; Daihatsu Sigra; Perodua Bezza, Axia

1KR-VET - Toyota Tank/Roomy, Raize; Daihatsu Thor, Rocky; Subaru Justy

| 1KR-FE type'14/16 (1.0 EFI VVT) |

Engine mechanical

The cylinder block - aluminum "open deck" with thin cast iron liners. The liners are fused into block and their special rough outer surface promotes strong connection. The wall thickness between the cylinders 7 mm only, no overhaul with reboring provided by manufacturer.

There is the spacer in the water jacket installed, it allows more intensive coolant circulation near the top of the cylinder, which improves heat dissipation and helps to more evenly thermally load.

1 - water jacket spacer, 2 - cylinder block

|

The axis of the crankshaft has been shifted by 8 mm relative to the cylinder axis lines ("desaxage"), thus reducing the lateral component of the force exerted by the piston to the cylinder wall, reducing wear.

a - cylinder axis, b - crankshaft axis

|

The crankshaft has 6 balance weights, 4 narrow journals and individual main bearing caps.

Pistons made of alloy, T-shaped with a small skirt (polymer anti friction coating). A drawback - piston pins are non full-floating, but press-fitted into the connecting rod. Oil ring is made of three parts.

1 - compression ring 1, 2 - compression ring 2, 3 - oil ring

|

The oil pan can be either simple or dual chamber.

When the engine is stopped, the outer and inner chambers communicate through the holes. When the engine is running, the oil from the sump 2 is in use mainly (to accelerate oil warm up). The float valve controls oil exchange between the chambers.

1 - oil level dipstick, 2 - oil pan 1, 3 - oil pan 2, 4 - oil strainer, 5 - drain plug. a - engine is stopped, b - engine is running, c - hole, d - float valve, e - lower oil level, f - upper oil level, g - oil in outer pan, h - oil in inner pan

|

The design of the cylinder head is a traditional one-part. The exhaust ports of all cylinders converge inside the head, which should accelerate the heating of the catalyst after starting. At high speed, on the contrary, the exhaust gas are cooled to expand the operating range, in which the stoichiometric mixture is maintained. The intake ports of type'16 are divided ("dual port").

1 - fuel injector , 2 - spark plug. a - intake port, b - exhaust port, c - exhaust side, d - merged port, e - EGR passage, f - intake side

|

Valvetrain - DOHC type, the angle between the intake and exhaust valves is 33.5°. For intake and exhaust the same coil springs of variable pitch are used. There is VVT (variable valve timing system) sprocket on the inlet camshaft, the range - 45°. More about Toyota operation principles - see "Toyota Variable Valve Timing. VVT-i (gen.IV)".

1 - timing chain, 2 - tension arm, 3 - chain tensioner, 4 - VVT controller, 5 - intake camshaft, 6 - exhaust camshaft

|

The valve clearance is adjusted by a various lifters, without adjusting washers or lash adjusters.

1 - cam, 2 - valve lifter, 3 - valve. b - DLC-coating

|

Timing drive - by single-row roller chain (pitch 8 mm) with hydraulic tensioner.

1 - chain guide, 2 - crankshaft sprocket, 3 - timing chain, 4 - tension arm, 5 - chain tensioner

|

The water pump and oil pump are installed in the cast timing chain cover.

The head cover is made of plastic, depending on the model it can be combined with the air filter housing.

Auxiliary drive - by single serpentine belt with automatic tensioner.

1 - generator, 2 - water pump, 3 - crankshaft pulley, 4 - compressor, 5 - tensioner

|

Lubrication

Trochoid oil pump is driven by crankshaft. Oil bypass is internal to the pump inlet.

1 - timing chain cover, 2 - oil pump rotor, 3 - oil pump housing

|

Oil nozzles that lubricate and cool the pistons are provided.

1 - VVT controller, 2 - VVT control valve, 3 - oil filter, 4 - oil pump, 5 - oil strainer, 6 - oil nozzle

|

Officially prescribed oil viscosity for 1KR-FE:

Cooling

Cooling system is classic: pump drive by serpentine belt, "cold" (78-82°C) mechanical thermostat, heated throttle body, cooled exhaust gas recirculation (EGR) valve.

1 - thermostat, 2 - throttle body, 3 - EGR valve, 4 - water pump. a - from heater radiator, b - to heater radiator, c - from radiator, d - to radiator

|

The coolant pump with a lightweight aluminum housing is mounted in the timing chain cover. The pump impeller is made of stainless steel.

1 - timing chain cover, 2 - water pump, 3 - volute chamber, 4 - pulley, 5 - rotor, 6 - shaft, 7 - pump body, 8 - bearing

|

Intake and exhaust

The location of the intake and exhaust manifolds - rear and front, respectively. The intake manifold is made of plastic, mounted to the cylinder head via the spacer (EGR gas dispenser). The exhaust manifold is made of stainless steel with an integrated catalyst.

1 - gasket, 2 - insulator, 3 - gasket, 4 - intake manifold, 5 - vacuum sensor. b - from EGR valve, c - gases through holes

|

1 - heat insulator, 2 - catalyst, 3 - EGR pipe

|

Fuel system / Engine control

1 - ignition coil, 2 - fuel injector, 3 - oxygen sensor 1, 4 - crank position sensor, 5 - knock sensor, 6 - camshaft position sensor, 7 - oxygen sensor 2, 8 - neutral position switch,

9 - engine coolant temperature sensor, 10 - EGR valve, 11 - vacuum sensor, 12 - throttle body, 13 - VVT control valve

|

Fuel injection - multipoint in-port. Fuel system - without a return line, with the pressure regulator, and the fuel filter, and EVAP canister built in pump module.

1 - fuel delivery pipe, 2 - fuel injector, 3 - fuel pressure regulator, 4 - charcoal canister, 5 - fuel tank, 6 - fuel pump module, 7 - fuel pump, 8 - fuel pump filter

|

Fuel delivery pipe - steel-stamped; its walls themselves serve as a damper for fuel pressure pulsations.

· Crankshaft position sensor - induction type or Hall effect type

· Camshaft position sensor - Hall effect type

· Knock sensor - flat piezoelectric type

· Manifold absolute pressure sensor (MAP) combined with the intake air temperature sensor

· Throttle position sensor - non-contact type

· Oxygen sensor - planar type, with heater

· Accelerator pedal position sensor - non-contact type

· Coolant temperature sensor

· Injector - with a 6-point nozzle

Type'16 engines are equipped with 6 twin injectors (see below for type'18).

Despite impressive compression ratios, all KR engines designed to use Regular / RON 91 gasoline.

Critical drawback - EGR system (valve control with stepper motor).

1 - insulator, 2 - EGR valve. a - coolant out, b - coolant in

|

PCV. 1 - air cleaner case, 2 - intake manifold, 3 - cylinder head cover, 4 - PCV valve, 5 - oil separator, 6 - crankcase

|

| 1KR-FE type'04 (1.0 EFI VVT) |

Without adhering to the chronological sequence, let's pay attention to the differences between the earlier and later versions and type'14 described above...

• Cylinder block - early type with a removable oil separator cover.

• Oil nozzles for pistons - not installed.

• Cylinder head - with a separate exhaust ports.

1 - fuel injector, 2 - spark plug, 3 - water jacket. a - 33.5°, b - intake side, c - exhaust side

|

• Accordingly, the exhaust manifold does indeed connects three separate port. In earlier versions, EGR pipe could be attached upstream the catalyst.

1,2 - heat insulator, 3,4 - gasket, 5 - EGR pipe, 6 - catalyst

|

• EGR dispenser between the intake manifold and cylinder head has been implemented since 2008.

• Fuel delivery pipe is made of plastic, the pulsation damper is external.

1 - fuel delivery pipe, 2 - fuel pulsation damper, 3 - fuel injector

|

• Most vehicles were not equipped with ETCS, but with a simple cable-driven mechanical throttle.

| 1KR-FE type'18 (1.0 EFI DVVT) |

The updated version of the engine also has a number of noticeable differences from type'14.

• Additional cooling channels in the cylinder block. The larger inlet port of the coolant pump to reduce resistance.

More complex composite spacer is used to equalize the temperature of the cylinder walls.

1 - spacer 1, 2 - spacer 2, 3 - spring, 4 - cylinder bore, 5 - water jacket, 6 - foam rubber

|

• VVT actuators for both camshafts are installed (DVVT - Dual Variable Valve Timing). Timing variations range - 41° for intake and 45° for exhaust.

1 - chain tension arm, 2 - chain tensioner, 3 - VVT controller (intake), 4 - timing chain, 5 - VVT controller (exhaust), 6 - intake camshaft, 7 - exhaust camshaft, 8 - chain guide

|

• Intake ports are separated (dual port).

1 - fuel injector, 2 - spark plug, a - intake port, b - exhaust port, c - exhaust side, d - merged port, e - EGR gas passage, f - intake side

|

• EGR cooler is used to further "efficiency" of exhaust gas recirculation.

1 - EGR valve. a - EGR cooler, b - water passage, c - exhaust gas passage

|

• Changes of the cooling circuits since EGR cooler installation.

1 - EGR cooler, 2 - EGR valve, 3 - throttle body, 4 - thermostat, 5 - water pump. a - from heater radiator, b - to heater radiator, c - from radiator, d - to radiator

|

• A few new components related to DVVT was added to the control system. Crankshaft position sensor - MRE type.

1 - ignition coil, 2 - VVT control valve (exhaust), 3 - oxygen sensor 1, 4 - knock sensor, 5 - crank position sensor, 6 - oxygen sensor 2, 7 - neutral position switch, 8 - engine coolant temperature sensor, 9 - camshaft position sensor (intake), 10 - fuel injector, 11 - vacuum sensor, 12 - throttle body, 13 - EGR valve, 14 - VVT control valve assembly (intake), 15 - camshaft position sensor (exhaust)

|

• Fuel system - "Dual Injector" type: two injectors for each cylinder.

1 - fuel delivery pipe, 2 - fuel injector, 3 - fuel pressure regulator, 4 - fuel filter, 5 - canister, 6 - fuel tank, 7 - pump module, 8 - fuel pump, 9 - fuel suction filter

|

The injector supplies the fuel into own port, as close to the valve as possible.

1 - fuel injector. a - intake port, b - tumble flow

|

Injectors - with a long 8-point nozzle.

The simplest engine of the series is not equipped with a variable valve timing system. Installed on models for emergency markets. A rather specific "reclined" version is installed in Daihatsu Himax.

Another version for emergency markets from Daihatsu, with VVT system. Looks like, but not a full copy of 1KR-FE type'14. A big advantage, at least for Perodua version, is the absence of EGR system.

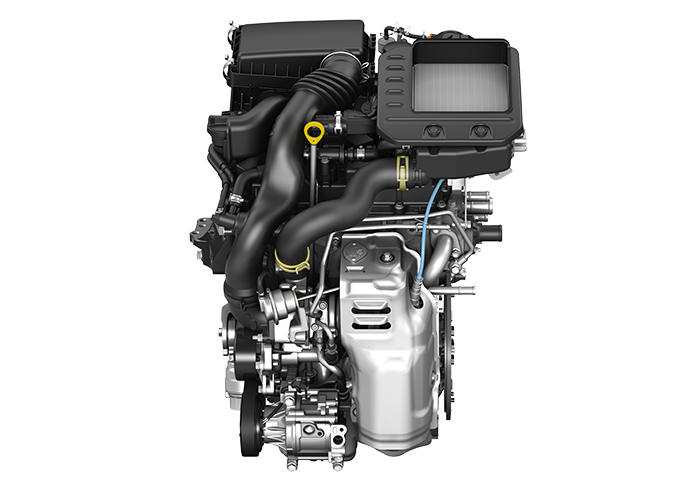

| 1KR-VET (1.0 EFI VVT Turbo) |

Turbocharged version based on type'16: "dual injector", dual intake ports, triple water jacket in the cylinder head, channels between exhaust valves, crankcase ventilation with ejector...

|

If only the engine that provides 70-80 PS per ton of vehicle weight can be considered normal... then 1KR-FE should be called as a usual representative of Toyota Corp. engines of the 2000s, but also affected by needless "ecological" features.

• Piston slap is a well-known phenomenon. Since the defect appeared even on the new cars (so non-roundness was a consequence of production defects but not wear), it was treated by warranty-covered replacement of the cylinder block and pistons/rings (mentioned in one of the service campaigns). Usually, an engine with such a defect can operate for a long time, and it is more economical to replace it with a second-hand engine after a complete failure.

• Cylinder liner and piston scratches (the sound effects are accompanied by an impressive oil consumption). In Southeast Asia, the repairers prefer to rebore the cylinder for 0.5 oversize pistons, without cylinder liners replacement.

• Piston ring stuck due to carbon deposits, timing chain wear, water pump leaks are commonplace, and KR is no exception.

• Mainly due to EGR (with a little "help" by the crankcase ventilation), the entire air intake pathes, valves, seats and combustion chambers are reliably supplied with soot. Also, in terms of the amount of solid deposits and oil sludge in the crankcase, under the head cover, in the separator etc. - KR engine is one of the dirtiest engines of Toyota corporation.

• The imbalance of the 3-cylinder engine only partially hides by its modest mass and developed mounts. However, with any deviation from the normal operation or idle speed dropping, it turns into a shaker. The recommendations are traditional - flushing the throttle and "re-adaptation", then cleaning of the intake duct, then mounts replacing, etc.

• Genuine service bulletins regarding 1KR-FE are also of some interest and sometimes allow not to reinvent the wheel:

·EG-0096T-0714 "KR Engine knocking noise" (23.07.2014, piston set and cylinder block replacement: 11401-40041 ⇒ 11401-40060, 11401-0Q011 ⇒ 11401-0Q030, 11401-40050 ⇒ 11401-40070)

·EG-0082T-0815 "KR Engine: Noise from the Exhaust Manifold" (27.08.2015, manifold mounting replacement)

·EG-0015T-0316 "1KR engine - Engine MIL on due to OCV malfunction (P0011)" (01.03.2016, VVT control valve replacement)

·EG-0009T-0115 "1KR-FE Oxygen sensor no.2 malfunction (P0139/P0141)" (10.07.2016, oxygen sensors replacement, reprogramming)

·EG-0061T-0916 "1KR: Oil pressure warning light on" (27.09.2016, oil pan and strainer replacement)

·EG-0059T-0617 "1KR: Abnormal noise from Thermostat" (23.06.2017, thermostat replacement)

·EG-0065T-0717 "Charge warning light is ON - DTC P162B and P161A" (17.07.2017, alternator replacement)

·EG-00035T-TME "KR Engine jerking when driving" (15.05.2018, camshaft sprocket position adjustment)

·EG-00036T-TME "1KR-FE Engine: Hard to start" (18.05.2018, starter and battery replacement)

·EG-00146T-TME "MIL ON (Blinks) triggered by Misfires DTC P030X" (12.04.2019, ignition coil wiring check)

·EG-00159T-TME "KR Engine: Air cleaner worn-out appearance" (24.06.2019, air filter housing mounting)

·EG-00187T-TME "KR Engine: Impossible to re-start DTCs P0341,P0366" (05.11.2019, reprogramming)

·CP-00501T-TME "1KR-FE, O2 sensor malfunction (DTC P0139)" (04.01.2021, oxygen sensor replacement)

• Toyota has refused to treat problems with the EGR cooler as a design defect and a warranty claim. Described in TSB EG-00691T-TME (02.02.2022).

|

Toyota engines review

·

AZ ·

MZ ·

NZ ·

SZ ·

ZZ ·

AR ·

GR ·

KR ·

NR ·

ZR ·

AD ·

GD ·

ND ·

VD ·

A25.M20 ·

F33 ·

G16 ·

M15 ·

V35 ·

|

|

|